Corrective and preventive action

Corrective and preventive action (CAPA, also called corrective action / preventive action, or simply corrective action) are improvements to an organization's processes taken to eliminate causes of non-conformities or other undesirable situations.[1] CAPA is a concept within good manufacturing practice (GMP), Hazard Analysis and Critical Control Points/Hazard Analysis and Risk-based Preventive Controls (HACCP/HARPC) and numerous ISO business standards. It focuses on the systematic investigation of the root causes of identified problems or identified risks in an attempt to prevent their recurrence (for corrective action) or to prevent occurrence (for preventive action).

Corrective actions are implemented in response to customer complaints, unacceptable levels of product non-conformance, issues identified during an internal audit, or adverse or unstable trends in product and process monitoring such as would be identified by statistical process control (SPC). Preventive actions are implemented in response to the identification of potential sources of non-conformity.

To ensure that corrective and preventive actions are effective, the systematic investigation of the root causes of failure is pivotal. CAPA is part of the overall quality management system (QMS).

Concepts

- Clearly identified sources of data which identify problems that will be investigated.

- Root cause analysis to identify the cause of a discrepancy or deviation and suggest corrective actions of a problem which is identified.

A common misconception is that the purpose of preventive action is to avert the occurrence of a similar potential problem. This process is all part of corrective action, because it is a process of determining such similarities that should take place in the event of a discrepancy.

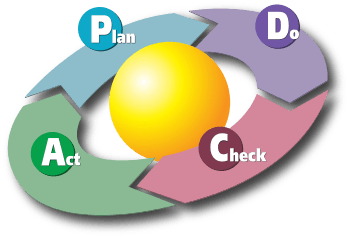

Preventive action is any proactive methodology used to determine potential discrepancies before they occur and to ensure that they do not happen (thereby including, for example, preventive maintenance, management review or other common forms of risk avoidance). Corrective and preventive actions both include investigation, action, review, and further action if so required. It can be seen that both fit into the PDCA (plan-do-check-act) philosophy as determined by the Deming-Shewhart cycle.

Investigations to root cause may conclude that no corrective or preventive actions are required, and additionally may suggest simple corrections to a problem with no identified systemic root cause. When multiple investigations end in no corrective action, a new problem statement with expanded scope may be generated, and a more thorough investigation to root cause performed.

Implementation of corrective and preventive actions is the path towards improvement and effectiveness of Quality Management Systems. Corrective actions is nothing but the action/s based on the problem identification. The problem or a non-conformance can be identified internally through staff suggestions, management reviews, document reviews or internal audits. Customer complaints / suggestions, customer rejections, non-conformities raised in customer / third party audits and recommendations by the auditors are the external sources which lead to find the root cause of the problem.

Root cause is the identification of the source of the problem where the person(s), system, process or external factor is identified as the cause of the non conformity. The root cause analysis can be done via 5 Whys or other methods, e.g. an Ishikawa diagram.

Corrective action is the re-work / rectification activity of the non conforming products as per ISO 9001:2008 (8.5.2).

Preventive action is prediction of problem and trying to avoid the occurrence (fail safe) through self initiated actions and analysis related with processes/products. This can be initiated with the help of active participation of staff members/workers through improvement teams, improvement meetings, opportunities for improvement during internal audits, management review, customer feedback and deciding own goals quantized in terms of business growth, reducing rejections, utilizing the equipment effectively, etc.

Medical devices and FDA compliance

In order to comply with FDA 21 CFR 820.100[3] medical device companies need to establish a CAPA process within their QMS. This part of the system may be paper or digital, but it is something that is looked for during an FDA visit.[4] In 2015 there were over 450 issues found with the CAPA systems for medical device companies. To have an FDA-compliant QMS system required the ability to capture, review, approve, control, and retrieve closed-loop processes.[5]

Examples of corrective actions

- Error Proofing

- Visible or Audible Alarms

- Process Redesign

- Product Redesign

- Training or enhancement/ modification of existing training programmes

- Improvements to maintenance schedules

- Improvements to material handling or storage

In some cases a combination of such actions may be necessary to fully correct the problem.

See also

References

- ↑ ISO 9000 Quality management system - Fundamentals and vocabulary. ISO. 2005.

- ↑ "Taking the First Step with PDCA". 2 February 2009. Retrieved 17 March 2011.

- ↑ "CFR - Code of Federal Regulations Title 21". www.accessdata.fda.gov. Retrieved 2016-05-20.

- ↑ "Does Your CAPA Process Need a CAPA?". SOLABS. Retrieved 2016-08-29.

- ↑ "Guidance for Industry- Q10 Pharmaceutical Quality System" (PDF). www.fda.gov. Retrieved 2016-08-29.

External links

- Good Manufacturing Practices for Pharmaceutical Ingredients (ICH)

- Quality Systems Approach to Pharmaceutical CGMP Regulations (FDA)

- Current Pharmaceutical links (FDA)

- Good Automated Manufacturing Practice (GAMP)

- Quality management system –Medical Devices – Guidance on corrective action and preventive action and related QMS processes