Double bottom

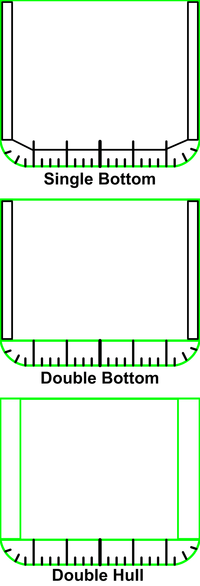

A double bottom is a ship hull design and construction method where the bottom of the ship has two complete layers of watertight hull surface: one outer layer forming the normal hull of the ship, and a second inner hull which is somewhat higher in the ship, perhaps a few feet, which forms a redundant barrier to seawater in case the outer hull is damaged and leaks.

The space in between the two bottoms is often used as storage tanks for fuel or ballast water, though fuel storage in the double bottom is not allowed for newbuilt ships since 2007, due to MARPOL 73/78.

Double bottoms are significantly safer than single bottoms. In case of grounding or other underwater damage, most of the time the damage is limited to flooding the bottom compartment, and the main occupied areas of the ship remain intact. For this reason, double bottoms have been required in all passenger ships for decades as part of the Safety Of Life At Sea or SOLAS Convention.

An even more extensive protection is available as a double hull, where the second hull layer extends up the sides of the ship as well as in the bottom.

A double bottom also conveniently forms a stiff and strong girder or beam structure with the two hull plating layers as upper and lower plates for a composite beam. This greatly strengthens the hull in secondary hull bending and strength, and to some degree in primary hull bending and strength.

Some of the advantages of double bottom in ships are:

- provide protection to hull in case of grounding

- provide great longitudinal strength

- can be used as tanks to carry oil, ballast water or fresh water (ventilated by a Gooseneck )

- helps to prevent pollution in case of liquid cargo (like oil in tankers)

- helps to maintain stability of ship

- the tank top acts as a platform for machinery and cargo