Terminal ballistics

Terminal ballistics, a sub-field of ballistics, is the study of the behavior and effects of a projectile when it hits its target.[1]

Terminal ballistics is relevant both for small caliber projectiles as well as for large caliber projectiles (fired from artillery). The study of extremely high velocity impacts is still very new and is as yet mostly applied to spacecraft design.

General

An early result is due to Newton; the impact depth of any projectile is the depth that a projectile will reach before stopping in a medium; in Newtonian mechanics, a projectile stops when it has transferred its momentum to an equal mass of the medium. If the impactor and medium have similar density this happens at an impact depth equal to the length of the impactor.

For this simple result to be valid, the arresting medium is considered to have no integral shear strength. Note that even though the projectile has stopped, the momentum is still transferred, and in the real world spalling and similar effects can occur.

Firearm projectiles

Classes of bullet

There are three basic classes of bullet:

- those designed for maximum accuracy at varying ranges

- those designed to maximize damage to a target by penetrating as deeply as possible

- those designed to avoid over-penetration of a target, by deforming to control the depth to which the bullet penetrates, which as a by-product, deals more damage inside the wound.

The third class may limit penetration by expanding or fragmenting.

Target shooting

For short range target shooting on ranges up to 50 meters (55 yd), aerodynamics are relatively unimportant and velocities are low. As long as the bullet is balanced so it does not tumble, the aerodynamics are unimportant. For shooting at paper targets, the best bullet is one that will punch a perfect hole through the target. These bullets are called wadcutters. They have a very flat front, often with a relatively sharp edge along the perimeter. The flat front punches out a large hole in the paper, close to, if not equal to, the full diameter of the bullet.

This allows for easy, unambiguous scoring of the target. Since cutting the edge of a target ring will result in scoring the higher score, fractions of an inch are important. Magazine-fed pistols may not reliably feed wadcutters because of the angular shape. To address this, the semiwadcutter is used. The semiwadcutter consists of a conical section that comes to a smaller flat, and a thin sharp shoulder at the base of the cone. The flat point punches a clean hole, and the shoulder opens the hole up cleanly. For steel targets, the concern is to provide enough force to knock over the target while minimizing the damage to the target. A soft lead bullet, or a jacketed hollow-point bullet or soft-point bullet will flatten out on impact (if the velocity at impact is sufficient to make it deform), spreading the impact over a larger area of the target, allowing more total force to be applied without damaging the steel target.

There are also specialized bullets designed for use in long range precision target shooting with high-powered rifles; the designs vary somewhat from manufacturer to manufacturer, but all are based on the MatchKing bullets introduced by the Sierra Bullet Company around 1963. Research in the 1950s by the U.S. Air Force discovered that bullets are more stable in flight for longer distances and more resistant to crosswinds if the center of gravity is somewhat to the rear of the center of pressure The MatchKing bullet (which is still in wide use and holds many records) is a hollow point design with a tiny aperture in the jacket at the point of the bullet and a hollow air space under the point of the bullet, where previous conventional bullets had had a lead core that went all the way up to the point.[2]

Other designs from other manufacturers may be anything from close copies of the MatchKing design to hollow point bullets with a deep, wide cavity containing a long, slender, pointed plastic or aluminum plug. In all these cases, the bullet is designed to have its center of gravity to the rear of its center of pressure. MatchKing-type hollow point bullets, as contrasted with hollow point bullets intended for hunting or police use, are not designed to flatten out on impact; this makes them a relatively poor choice for hunting, as they tend to perform erratically and unpredictably upon entering an animal's body—they may tumble, or break apart, though most often they punch straight through making a narrow wound that usually does not cause death quickly. The U.S. military now issues ammunition to snipers that use bullets of this type. In 7.62×51mm NATO, M852 Match and M118LR ammunition are issued, both of which use Sierra MatchKing bullets; in 5.56×45mm NATO, those U.S. Navy and U.S. Marine snipers who use accurized M16-type rifles are issued the Mk 262 Mod 0 cartridge developed jointly by Black Hills Ammunition and Crane Naval Surface Warfare Center, using a bullet manufactured by Sierra Bullets that was cannelured according to military specifications for this project.

In 1990, the U.S. Army Adjutant General's Office issued a legal opinion holding that the Sierra MatchKing bullet, despite being an open-tip design, is not designed specifically to cause greater damage or suffering in a human target, and in fact normally does not create a wound readily distinguishable from wounds caused by conventional full metal jacket bullets, and is therefore in their opinion legal under the Hague Convention for use in war.[3]

For ultra long range precision target shooting with high-powered rifles and military sniping, radically designed very-low-drag (VLD) bullets are available that are generally produced out of rods of mono-metal alloys on CNC lathes. The driving force behind these projectiles is the wish to enhance the practical maximum effective range beyond normal standards. To achieve this, the bullets have to be very long and normal cartridge overall lengths often have to be exceeded. Common rifling twist rates also often have to be tightened to stabilize very long projectiles. Such commercially nonexistent cartridges are termed "wildcats". The use of a wildcat based (ultra) long-range cartridge demands the use of a custom or customized rifle with an appropriately cut chamber and a fast-twist bore.

Maximum penetration

For use against armored targets, or large, tough game animals, penetration is the most important consideration. Focusing the largest amount of momentum on the smallest possible area of the target provides the greatest penetration. Bullets for maximum penetration are designed to resist deformation on impact, and usually are made of lead that is covered in a copper, brass, or mild steel jacket (some are even solid copper or bronze alloy). The jacket completely covers the front of the bullet, although often the rear is left with exposed lead (this is a manufacturing consideration: the jacket is formed first, and the lead is swaged in from the rear).

For penetrating substances significantly harder than jacketed lead, the lead core is supplemented with or replaced with a harder material, such as hardened steel. Military armor-piercing small arms ammunition is made from a copper-jacketed steel core; the steel resists deformation better than the usual soft lead core leading to greater penetration. The current NATO 5.56mm SS109 (M855) bullet uses a steel-tipped lead core to improve penetration, the steel tip providing resistance to deformation for armor piercing, and the heavier lead core (25% heavier than the previous bullet, the M193) providing increased sectional density for better penetration in soft targets. For larger, higher-velocity calibers, such as tank guns, hardness is of secondary importance to density, and are normally sub-caliber projectiles made from tungsten carbide, tungsten hard alloy or depleted uranium fired in a light aluminum or magnesium alloy (or carbon fibre in some cases) sabot.

Many modern tank guns are smoothbore, not rifled, because practical rifling twists can only stabilize projectiles, such as an armour-piercing fin-stabilized discarding sabot (APFSDS), with a length-to-diameter ratio of up to about 5:1, the spin imposed by rifling interferes with shaped-charge rounds, and also because the rifling adds friction and reduces the velocity it is possible to achieve. To get the maximum force on the smallest area, anti-tank rounds have aspect ratios of 10:1 or more. Since these cannot be stabilized by rifling, they are built instead like large darts, with fins providing the stabilizing force, negating the need for rifling. These subcaliber rounds are held in place in the bore by sabots. The sabot is a light material that transfers the pressure of the charge to the penetrator, then is discarded when the round leaves the barrel.

Controlled penetration

The final category of bullets is that intended to control penetration so as not to harm anything behind the target. Such bullets are used primarily for hunting and civilian antipersonnel use; they are not generally used by the military, since the use of expanding bullets in international conflicts is prohibited by the Hague Convention and because these bullets have less chance of penetrating modern body armor. These bullets are designed to increase their surface area on impact, thus creating greater drag and limiting the travel through the target. A desirable side effect is that the expanded bullet makes a larger hole, increasing tissue disruption and speeding incapacitation.

In some applications, preventing exit from the rear of the target is also desirable. A bullet that penetrates through-and-through tends to cause more profuse bleeding, allowing a game animal to be bloodtrailed more easily. On the other hand, a perforating bullet can then continue on (likely not coaxial to the original trajectory due to target deflection) and might cause unintended damage or injury. Frangible bullets, made of tiny fragments held together by a weak binding, are often sold as an "ultimate" expanding bullet, as they will increase their effective diameter by an order of magnitude. When they work, they work extremely well, causing massive trauma to the target. On the other hand, when they fail, it is due to underpenetration, and the damage to the target is superficial and leads to very slow incapacitation.

Flat point

The simplest maximum disruption bullet is one with a wide, flat tip. This increases the effective surface area, as rounded bullets can allow tissues to "flow" around the edges. It also increases drag during flight, which decreases the depth to which the bullet penetrates. Older centerfire rifles with tube magazines were designed to be used with flat-point bullets. Flat-point bullets, with fronts of up to 90% of the overall bullet diameter, are usually designed for use against large or dangerous game. They are often made of unusually hard alloys, are longer and heavier than normal for their caliber, and even include exotic materials such as tungsten to increase their sectional density.

These bullets are designed to penetrate deeply through muscle and bone, while causing a wound channel of nearly the full diameter of the bullet. These bullets are designed to penetrate deeply enough to reach vital organs from any shooting angle and at a far enough range. One of the hunting applications of the flat point bullet is large game such as bear hunted with a handgun in a .44 Magnum or larger caliber. More common than hunting is its use in a defensive "bear gun" carried by outdoorsmen. The disadvantage of flat point bullets is the reduction in aerodynamic performance; the flat point induces much drag, leading to significantly reduced velocities at long range.

Expanding

More effective on lighter targets are the expanding bullets, the hollow point bullet and the soft point bullet. These are designed to use the hydraulic pressure of muscle tissue to expand the bullet. The hollow point peels back into eight or nine connected pieces causing it to expand the damaged area. The hollow point fills with body water on impact, then expands as the bullet continues to have water pushed into it. This process is called mushrooming, as the ideal result is a shape that resembles a mushroom—a cylindrical base, topped with a wide surface where the tip of the bullet has peeled back to expose more area to create more drag while traveling through a body. A copper-plated hollowpoint loaded in a .44 Magnum, for example, with an original weight of 240 grains (15.55 g) and a diameter of 0.43 inch (11 mm) might mushroom on impact to form a rough circle with a diameter of 0.70 inch (18 mm) and a final weight of 239 grains (15.48 g).

This is excellent performance; almost the entire weight is retained, and the frontal surface area increased 63%. Penetration of the hollowpoint would be less than half that of a similar nonexpanding bullet, and the resulting wound or permanent cavity would be much wider.

Fragmenting

This class of projectile is designed to break apart on impact, causing an effect similar to that of a frangible projectile, whilst being of a construction more akin to that of an expanding bullet. Fragmenting bullets are usually constructed like the hollowpoint projectiles described above, but with deeper and larger cavities. They may also have thinner copper jackets in order to reduce their overall integrity. For the purposes of aerodynamic efficiency the tip of the hollowpoint will often be tipped with a pointed polymer 'nose'. These bullets are typically fired at high velocities to maximize their fragmentation upon impact. In contrast to a hollowpoint which attempts to stay in one large piece retaining as much weight as possible whilst presenting the most surface area to the target, a fragmenting bullet is intended to break up into many small pieces almost instantly.

This means that all the kinetic energy from the bullet is transferred into the target in a very short period of time. The most common application of this bullet is the shooting of small vermin, such as prairie dogs. The effect of these bullets is quite dramatic, often resulting in the animal being blown apart upon impact. However, on larger game fragmenting ammunition provides inadequate penetration of vital organs to ensure a clean kill; instead, a "splash wound" may result. This also limits practical use of these rounds to supersonic (rifle) rounds, which have a high enough kinetic energy to ensure a lethal hit. The two main advantages of this ammunition are that it is very humane, as a hit almost anywhere on most small vermin will ensure an instant kill, and that instead of dangerously and uncontrollably ricocheting off surfaces, the bullet harmlessly breaks apart. Fragmenting bullets should not be confused with frangible bullets (see below).

Frangible

The last category of expanding bullets is frangible bullets. These bullets are designed to break up on impact, which results in a huge increase in surface area. The most common of these bullets are made of small diameter lead pellets, placed in a thin copper shell and held in place by an epoxy or similar binding agent. On impact, the epoxy shatters and the copper shell opens up, much like a hollowpoint. The individual lead balls then spread out in a wide pattern, and due to their low mass to surface area ratio, stop very quickly. Similar bullets are made out of sintered metals, which turn to powder upon impact. These bullets are usually restricted to pistol cartridges, as the nonhomogenous cores tend to cause inaccuracies that, while acceptable at short pistol ranges, are not acceptable for the typical range at which rifles are used.

One interesting use of the sintered metal rounds is in shotguns in hostage rescue situations; the sintered metal round is used at near-contact range to shoot the lock mechanism out of doors. The resulting metal powder will immediately disperse after knocking out the door lock, and cause little or no damage to occupants of the room. Frangible rounds are also used by armed security agents on aircraft. The concern is not depressurization (a bullet hole will not depressurise an airliner), but over penetration and damage to vital electrical or hydraulic lines, or injury to an innocent bystander by a bullet that travels through a target's body completely instead of stopping in the body.

Also used are bullets similar to hollowpoint bullets or soft point bullets whose cores and/or jackets are deliberately weakened to cause deformation or fragmentation upon impact. The Warsaw Pact 5.45×39mm M74 assault rifle round exemplifies a trend that is becoming common in the era of high velocity, small caliber military rounds. The 5.45×39mm uses a steel-jacketed bullet with a two-part core, the rear being lead and the front being steel with an air pocket fore most. Upon impact, the unsupported tip deforms, bending the bullet nose into a slight "L" shape. This causes the bullet to tumble in the tissue, thus increasing its effective frontal surface area by traveling sideways more often than not.

This does not violate the Hague Convention, as it specifically mentions bullets that expand or flatten in the body. The NATO SS109 also tends to bend at the steel/lead junction, but with its weaker jacket, it fragments into many dozens of pieces. NATO 7.62 mm ball manufactured by some countries, such as Germany and Sweden, are also known to fragment due to jacket construction.

Other bullets in use by militaries are quite back heavy, due to a long, sharp point created in an attempt to get the maximum ballistic coefficient (see external ballistics). These bullets will flip over after impact, then settle into a stable, back first orientation before stopping. The Swiss military actually redesigned their 5.56mm assault rifle bullet to prevent this, to more fully comply with the spirit of the Hague Convention, though according to some sources the present GP90 5.56×45mm Swiss assault rifle ammunition was actually designed as an armor-piercing bullet, because, in the 1980s, it was perceived that the Soviets and their Warsaw Pact allies were going to issue soft body armor to infantry units on a wide basis, but after the end of the Cold War, the Bofors corporation, having spent a great deal of money on developing the new bullet, changed the sales pitch in order to sell it to the Swiss government.

It might seem that if the whole purpose of a maximum disruption round is to expand to a larger diameter, it would make more sense to start out with the desired diameter rather than relying on the somewhat inconsistent results of expansion on impact. While there is merit to this (there is a strong following of the .45 ACP, as compared to the .40 S&W and 0.355 in diameter 9×19mm, for just this reason) there are also significant downsides. A larger diameter bullet is going to have significantly more drag than a smaller diameter bullet of the same mass, which means long range performance will be significantly degraded. A larger diameter bullet also means more space is required to store the ammunition, which means either bulkier guns or smaller magazine capacities. The common trade-off when comparing .45 ACP, .40 S&W, and 9×19mm pistols is a 7- to 14-round capacity in the .45 ACP vs. a 10- to 16-round capacity in the .40 S&W vs. a 13- to 19-round capacity in the 9×19mm.

Although several .45-caliber pistols are available with high-capacity magazines (Para Ordnance being one of the first in the late 1980s) many people find the wide grip required uncomfortable and difficult to use. Especially where the military requirement of a nonexpanding round is concerned, there is fierce debate over whether it is better to have fewer, larger bullets for enhanced terminal effects, or more, smaller bullets for increased number of potential target hits.

Selecting for terminal performance

The standard medium for testing bullets for performance on tissue is ballistic gelatin. Tests have shown that properly prepared and calibrated 10% (by mass) gelatin at 4 degrees Celsius correlates very closely to observed performance in the muscle tissue of a living swine. Performance is generally graded with two factors, the maximum depth of penetration and the size of the cavity formed in the gelatin by the bullet impact. The size of the cavity represents the distance which tissue is thrown radially outward due to "splash." The penetration represents how far into the tissue the bullet will ultimately penetrate.

Unfortunately, improperly prepared gelatin is a poor medium for evaluating actual effectiveness. The observed "tissue splash", usually referred to as "temporary cavitation", is not an indication of terminal performance in an animal, as gelatin has a much lower elastic limit than most living tissues; a force that tears a gelatin block in half may result in nothing more than slight bruising if applied to living flesh.

Gelatin as a testing medium is greatly misunderstood. Temporary cavitation is almost meaningless. Permanent cavitation is of value, however, as it is the penetration multiplied by the expanded bullet's diameter. It predicts actual tissue damage. The value is knowing what the final expanded shape of the bullet will be and how deep it will penetrate. That is what the gelatin medium does best. One does not know what the terminal shape of the bullet will be until it is actually tested. US Army retired, Col Martin Fackler's, (MD) work was the comparison of gelatin performance tests with 200 actual cadavers. He found that properly prepared gelatin was a reliable medium for predicting depth of penetration and bullet deformation. Large diameter bullets make big holes and heavy bullets make deep holes. However, over expanded bullets may not penetrate deeply enough. The point to remember is, placement is the single most important factor in immediate incapacitation. A bullet must penetrate deeply enough to reach and damage vital organs, such as the heart. Immediate incapacitation occurs when the central nervous system is interrupted, either by contact damage or by anoxia from blood loss. Even with a punctured heart, an assailant can function for about 11 seconds. (Fackler,M.L., M.D., Director, Wound Ballistics Laboratory, Letterman Army Institute of Research, Presidio, San Francisco CA. "Bullet Performance Misconceptions" International Defense Review 3, 369-370, 1987)

Penetration figures may not be accurate, as some testers may not calibrate their gelatin. The standard calibration is 85 mm of penetration when shot by a standard .177 caliber steel bb traveling at 180 m/s (590 ft/s). Uncalibrated gelatin may show a variance of up to + or - 50% from calibrated gelatin. Further, animals' skin resists penetration much more than the muscle tissue which gelatin simulates. Human skin tissue on the torso resists penetration as much as 50 mm (2 in) of muscle, and horses' skin is the equivalent of approximately 200 mm (7.9 in).

For a quick incapacitation, a hit to a vital, blood-bearing organ or the central nervous system is needed, so a bullet that will penetrate to the depth required for such a hit should be chosen. When hunting groundhogs, for example, a bullet that expands quickly to form a large cavity with minimum penetration would be the best choice. When hunting deer, a bullet that penetrates deeper is required; this can be accomplished by either limiting expansion (twice the original width is often regarded as ideal), or by using a more powerful cartridge.

For hunting bear, yet more penetration is required. The pattern is, of course, that the larger the animal, the deeper its vital organs will be located, and therefore a firearm, cartridge, and bullet type should be chosen that will be able to reach the vital organs and kill humanely.

For dangerous game, especially deep penetration is critical; the reason for this is that the shooter cannot always choose their shots. If a hunter finds himself staring at a deer's hindquarters, it is very unlikely that he or she will choose to fire at that deer anyway, in the hopes that their bullet will be able to reach a vital organ through several layers of muscle and gut. The better choice in that scenario would be to wait until the deer decides to turn around. A lion, however, may decide to charge at a person other than the shooter, presenting a much less than optimal shooting angle.

To hit the vital organs on a large game animal requires penetrating the thick fat and muscle tissue surrounding the chest cavity, and quite often bone as well. A hard, nondeforming bullet is often chosen, though many modern rifle calibers are quite capable of killing 1,000 lb (450 kg) elk and similar-sized animals with a deforming bullet; even the venerable .30-06 is up to the task, provided it has a powerful enough load. Elephant hunters normally attempt to shoot for the brain, which is much smaller than the size of the elephant's head, and so must be targeted quite precisely, and requires a firearm and bullet capable of punching through a foot (300 mm) or more of tough, albeit hollow, bone and reaching the brain.

Non-military defensive purposes

The rules of engagement for non-military use of firearms usually require that a life, or in some jurisdictions, property, must be in immediate danger, for shots to be fired. Under such circumstances, the goal is to incapacitate the target as quickly as possible, to prevent the harm from being done. In most cases, the shots are fired from a handgun, which is, compared to a rifle, very much underpowered. Handguns are also very inaccurate in the hands of inexperienced shooters, and the average defensive shooter is under a great deal of stress, which further degrades accuracy. These factors combine to require extremely effective terminal ballistics to provide swift incapacitation of the target under far less than ideal circumstances.

Humans walk upright and present relatively unprotected vital organ targets from some angles, and have substantially thinner skin, so the bare minimum penetration is lower than for most large game. However, cross-torso shots and shots that must first penetrate an arm before entering the torso are relatively common in defensive shooting scenarios.

Bullets for use on humans are usually designed to comply with the FBI's penetration requirement of 12 to 18 inches (30 to 46 cm), which is based on the IWBA's requirement of 12.5 to 14 inches (32 to 36 cm). This is to ensure that the bullet can reach a vital blood-bearing organ or central nervous system structure from most angles. Frangible rounds, while they are sold for defensive purposes, are not well suited for the role, as they generally penetrate less than 10 inches (25 cm), and are therefore prone to failure when they must pass through nonvital tissues, such as a hand or arm.

Hollowpoint bullets normally expand most when at their highest velocity; that is, when entering the target. As they expand, they slow. Hollowpoint bullets may not expand when they strike sheet metal, glass, or bulky clothing before the target. These preliminary obstacles can either fill the hollowpoint cavity or deform the lips of the cavity. Either of these effects can prevent the high internal hydraulic pressure necessary to make the hollowpoint round expand. Some modern hollow-point defensive rounds have a soft polymer tip to help them pass through clothing without being plugged by cloth fragments.

For in-depth information on the mechanisms (and misconceptions) by which bullets incapacitate living targets, see the article on stopping power.

Large caliber

The purpose of firing a large calibre projectile is not always the same. For example, one might need to create disorganisation within enemy troops, create casualties within enemy troops, eliminate the functioning of an enemy tank, or destroy an enemy bunker. Different purposes of course require different projectile designs.

Many large calibre projectiles are filled with a high explosive which, when detonated, shatters the shell casing, producing thousands of high velocity fragments and an accompanying sharply rising blast overpressure. More rarely, others are used to release chemical or biological agents, either on impact or when over the target area; designing an appropriate fuse is a difficult task which lies outside the realm of terminal ballistics.

Other large-calibre projectiles use bomblets (sub-munitions), which are released by the carrier projectile at a required height or time above their target. For US artillery ammunition, these projectiles are called Dual-Purpose Improved Conventional Munition (DPICM), a 155 mm M864 DPICM projectile for example contains a total of 72 shaped-charge fragmentation bomblets. The use of multiple bomblets over a single HE projectile allows for a denser and less wasteful fragmentation field to be produced. If a bomblet strikes an armoured vehicle, there is also a chance that the shaped charge will (if used) penetrate and disable the vehicle. A negative factor in their use is that any bomblets that fail to function go on to litter the battlefield in a highly sensitive and lethal state, causing casualties long after the cessation of conflict. International conventions tend to forbid or restrict the use of this type of projectile.

Some anti-armour projectiles use what is known as a shaped charge to defeat their target. Shaped charges have been used ever since it was discovered that a block of high explosives with letters engraved in it created perfect impressions of those letters when detonated against a piece of metal. A shaped charge is an explosive charge with a hollow lined cavity at one end and a detonator at the other. They operate by the detonating high explosive collapsing the (often copper) liner into itself. Some of the collapsing liner goes on to form a constantly stretching jet of material travelling at hypersonic speed. When detonated at the correct standoff to the armour, the jet violently forces its way through the target's armour.

Contrary to popular belief, the jet of a copper-lined shaped charge is not molten, although it is heated to about 500 °C. This misconception is due to the metal's fluid-like behaviour, which is caused by the massive pressures produced during the explosives detonation causing the metal to flow plastically. When used in the anti-tank role, a projectile that uses a shaped-charge warhead is known by the acronym HEAT (high-explosive anti-tank).

Shaped charges can be defended against by the use of explosive reactive armour (ERA), or complex composite armour arrays. ERA uses a high explosive sandwiched between two, relatively thin, (normally) metallic plates. The explosive is detonated when struck by the shaped charge’s jet, the detonating explosive sandwich forces the two plates apart, lowering the jets’ penetration by interfering with, and disrupting it. A disadvantage of using ERA is that each plate can protect against a single strike, and the resulting explosion can be extremely dangerous to nearby personnel and lightly armoured structures.

Tank fired HEAT projectiles are slowly being replaced for the attack of heavy armour by so-called "kinetic energy" penetrators. Ironically, it is the most primitive (in-shape) projectiles that are hardest to defend against. A KE penetrator requires an enormous thickness of steel, or a complex armour array to protect against. They also produce a much larger diameter hole in comparison to a shaped charge and hence produce a far more extensive behind armour effect. KE penetrators are most effective when constructed of a dense tough material that is formed into a long, narrow, arrow/dart like projectile.

Tungsten and depleted uranium alloys are often used as the penetrator material. The length of the penetrator is limited by the ability of the penetrator to withstand launch forces whilst in the bore and shear forces along its length at impact.

Hypervelocity

The study of projectile impacts with hypersonic velocities greater than several kilometres per second is an area of active research.[4]

Such impacts are not yet used in military situations—although active military research in hypersonic weapons is going on[5]—but can arise from meteorite impacts on spacecraft. The impact of extremely small, extremely fast particles is of interest in designing spacecraft to withstand erosion due to micrometeoroids and small orbital debris.

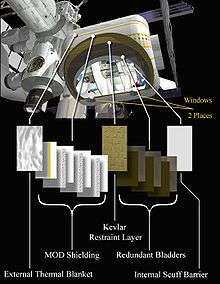

Ceramic fiber woven shields offer better protection to hypervelocity (>2 km/s) particles than aluminum shields of equal weight,[7] and whipple shields also offer some protection from orbital micrometeroids.[8]

One design for protection from small space debris and micrometeroids was the multi-layer shell of NASA's TransHab space habitation module.[9] This technology was subsequently licensed by private company Bigelow Aerospace which is pursuing a similar scheme for a private space station design.[10] Two Bigelow inflatable-technology space craft, Genesis I and Genesis II, built with proprietary extensions of the NASA technology, were launched in 2006.[11] As of April 2009, both spacecraft were still operating nominally after more than 10,000 orbits and traveling over 270 million miles, demonstrating significant real-world validation testing of a fabric-based ballistic shield.[12][13]

Accelerating projectiles up to such speeds on earth is currently difficult; light-gas guns are currently the most common techniques for producing such speeds, although linear motors, railguns, coilguns and ram accelerators are also possibilities undergoing active research. NASA has been using two-stage light-gas guns to simulate 2.2-cm diameter micrometeoid and orbital debris at velocities in excess of 7.5 km/s for decades[14] and in 2005, Bigelow Aerospace utilized an earthbound test apparatus firing 1.7-cm-diameter aluminum projectiles into its inflatable spacecraft multilayer shield technology at 7 km/s.[15]

Gallery

Wound ballistics for various Soviet cartridges

Wound ballistics for various Soviet cartridges AK-47 7.62x39mm wound ballistics

AK-47 7.62x39mm wound ballistics AK-74 5.45x39mm wound ballistics

AK-74 5.45x39mm wound ballistics M16 5.56x45mm wound ballistics

M16 5.56x45mm wound ballistics M16A2 M855 5.56X45mm NATO wound ballistics

M16A2 M855 5.56X45mm NATO wound ballistics

See also

- Forensic ballistics

- Gunshot injury

- Hydrostatic shock

- Kinetic energy penetrator

- Stopping power

- Table of handgun and rifle cartridges

- Taylor KO factor

- Vaporific effect

References

- ↑ Terminal Ballistics Test and Analysis Guidelines for the Penetration Mechanics Branch - BRL

- ↑ Gyroscopic Stability of Open Tipped Match Style Rifle Bullets by ELYA R. COURTNEY AND MICHAEL W. COURTNEY

- ↑ Parks, W. Hays (12 October 1990). "MEMORANDUM FOR COMMANDER, UNITED STATES ARMY SPECIAL OPERATIONS COMMAND; SUBJECT: Sniper Use of Open-Tip Ammunition". The Gun Zone. Retrieved 23 June 2011.

- ↑ Thompson, Mark (2012-08-27). "Bigelow's inflatable space stations". SEN. Retrieved 2012-09-09.

a material called Vectran, twice as strong as Kevlar and present in several layers of the 15cm thick skin of the Genesis [space]craft. The flexible nature of the material results in further added safety for potential station inhabitants, a benefit supported by laboratory tests. It was found that micrometeoroids that would puncture the rigid skin of the International Space Station only penetrated half way through the skin of the Genesis craft. ... Hypervelocity tests conducted by Bigelow Aerospace have shown that this shield provides greater protection than a traditional aluminium can design.

- ↑ Brendan Borrell (February 6, 2008). "Electromagnetic Railgun Blasts Off". Technology Review.

- ↑ International Space Station Imagery, image S99-05362, "Computer Generated Still -- Cutaway of the TransHab Module shell showing the various layers," 2001-08-30

- ↑ Ceramic Fabric Offers Space Age Protection, 1994 Hypervelocity Impact Symposium

- ↑ , Karen Rodriguez, White Sands Test Facility (WSTF) Remote Hypervelocity Test Laboratory (RHTL), Jul 2009.

- ↑ Kim Dismukes (curator) (2003-06-27). "TransHab Concept". NASA.gov. Retrieved 2007-06-10.

- ↑ Schrimpsher, Dan (2006-08-21). "Interview: TransHab developer William Schneider". TheSpaceReview.com. Retrieved 2007-06-10.

- ↑ Company sees future in space, Las Vegas Review-Journal, 15 Aug 2007, Accessed 3 Oct 2009

- ↑ Malik, Tariq (2008-05-09). "Private Space Station Prototype Hits Orbital Milestone". Space.com. Retrieved 2009-10-03.

- ↑ "Genesis II Completes 10,000 Orbits!". BigelowAerospace.com. 2009-04-23. Retrieved 2009-10-03.

- ↑ , Karen Rodriguez, White Sands Test Facility (WSTF) Remote Hypervelocity Test Laboratory (RHTL), Dec 2011.

- ↑ Putting Up the Ritz: Can pneumatic buildings breathe life into space tourism?, James Oberg, IEEE Spectrum, Feb 2007.

External links

- Ballistic gelatin test results & pictures

- Shooting Holes in Wounding Theories: The Mechanics of Terminal Ballistics

- Shaped charges

- Handgun Wounding Factors and Effectiveness, a 1989 FBI publication