Litz wire

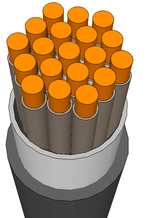

Litz wire is a type of cable used in electronics to carry alternating current. The wire is designed to reduce the skin effect and proximity effect losses in conductors used at frequencies up to about 1 MHz.[1] It consists of many thin wire strands, individually insulated and twisted or woven together, following one of several carefully prescribed patterns[2] often involving several levels (groups of twisted wires are twisted together, etc.). The result of these winding patterns is to equalize the proportion of the overall length over which each strand is at the outside of the conductor, an effect not achieved with simple twisted-strand hookup wire.

The term litz wire originates from Litzendraht (coll. Litze), German for braided/stranded wire[3] or woven wire.[4]

Principle of operation

Litz wire reduces the degree of the skin effect and the proximity effect.

Skin effect

The resistance of a conductor at DC (0 Hz) depends on its cross-sectional area. A conductor with a larger area has a lower resistance. The resistance also depends on frequency because the effective cross-sectional area changes with frequency. For alternating currents (AC), the skin effect causes the resistance to increase with increasing frequency.

For low frequencies, the effect is negligible. For AC at frequencies high enough that the skin depth is small compared to the conductor size, the skin effect causes most of the current to flow near the conductor's surface. At high enough frequencies, the interior of a large conductor does not carry much current.

- At 60 Hz, the skin depth of a copper wire is about 1⁄3 inch (8.5 mm).

- At 60,000 Hz (60 kHz), the skin depth of copper wire is about 0.01 inches (0.25 mm).

- At 6,000,000 Hz (6 MHz) [5] the skin depth of copper wire is about 0.001 inches (25 µm).

Round conductors larger than a few skin depths do not conduct much current near their axis, so the central material is not used effectively.

When larger area conductors are needed, measures are taken to reduce amount of material that does not carry current. One method is the use of a hollow pipe with a conducting wall with a thickness approximately that of the skin-depth at intended frequency.

Litz wire is another method, which employs a stranded wire with individually insulated conductors (forming a bundle). Each thin conductor is less than a skin-depth, so an individual strand does not suffer an appreciable skin effect loss. The strands must be insulated from each other—otherwise all the wires in the bundle would short together, behave like a single large wire, and still have skin effect problems. Furthermore, the strands cannot occupy the same radial position in the bundle over long distances: the electromagnetic effects that cause the skin effect would still disrupt conduction. The weaving or twisting pattern of the wires in the bundle is designed so that the individual strands are on the outside of the bundle for a distance (where the EM field changes are smaller and the strand sees low resistance), and are inside for a distance (where the EM field changes are the strongest and the resistance is higher). If each strand has a comparable impedance, current is distributed equally among every strand within the cable. This allows the interior of the litz wire to contribute to the overall conductivity of the bundle.

Another way to explain the benefit of Litz braiding is as follows: the magnetic fields generated by current flowing in the strands are in directions such that they have a reduced tendency to generate an opposing electromagnetic field in the other strands. Thereby, for the wire as a whole, the skin effect and associated power losses when used in high-frequency applications are reduced. The ratio of distributed inductance to distributed resistance is increased, relative to a solid conductor, resulting in a higher Q factor at these frequencies.

Proximity effect

In cases involving multiple wires, or multiple turns, such as windings in transformers and inductors, the proximity effect causes losses to increase at high frequency even sooner and more rapidly than does skin effect.

Effectiveness

Terman (1943, pp. 37, Table 18, 78) provides an expression for the ratio of resistance to alternating current to resistance to direct current for an isolated litz wire.[6] It does not apply to windings with multiple turns. An expression for the resistance ratio in windings is given by Sullivan (1999) at Eqn 2 and Appendix A (page 289).

Litz wire is very effective below 500 kHz; it is rarely used above 2 MHz as it is much less effective there.[1] At frequencies above about 1 MHz, the benefits become gradually offset by the capacitive build-up between the strands.[7] At microwave frequencies, the skin depth is much smaller than the diameter of the strands, and the current that is forced through the inner strands induces strong eddy currents in the outer strands, which negates the benefits of litz wire to the point where it performs much worse than solid wire of the same diameter.

Litz wire has a higher impedance per unit cross-sectional area but litz wires can be used at thicker cable sizes, hence reducing or maintaining cable impedance at higher frequencies.[8]

Applications

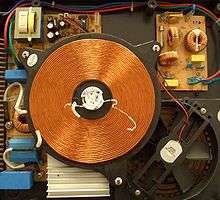

Litz wire is used to make inductors and transformers, especially for high frequency applications where the skin effect is more pronounced and proximity effect can be an even more severe problem. Litz wire is one kind of stranded wire, but, in this case, the reason for its use is not the usual one of avoiding complete wire breakage due to material fatigue.

Litz wire is frequently found in power applications in frequencies ranging between lower tens to higher hundreds kilohertz, namely induction cookers and transmitters of inductive chargers (e.g. the Qi standard). Multiple parallel twisted strands of enameled wires can be found also in transformers in some switching power supplies.

WWVB transmitting station

NIST uses litz wire in the time code broadcasting station WWVB. The station transmits on 60 kHz. The litz wire consists of 6075 strands of #36 (0.127 mm) magnet wire in a cable ¾ inch (19 mm) in diameter. Litz wire is used in an impressive variable inductor. (Hansen & Gish 1995)

See also

References

- 1 2 Terman (1943, p. 37)

- ↑ Litz Wire Types & Construction, New England Wire Technologies, 2005

- ↑ See English translation of Litzendraht. See translation of Litze (lace, strand, braiding, braid on military uniform) and translation of Draht (wire, filament, strand). See also German translations of wire.

- ↑ http://www.mwswire.com/litzmain.htm, http://www.wiretron.com/litz.html, and http://www.litz-wire.com/applications.html translate Litzendraht to woven wire

- ↑ Litz wire is impractical at 6MHz; see Terman (1943, p. 37).

- ↑ Terman cites Butterworth (1926)

- ↑ http://www.micrometals.com/appnotes/appnotedownloads/ipc4hqi.pdf

- ↑ Skindepth, Litz wire, braided conductors and resistance, W8JI.

- Butterworth, S. (August 1926), "Effective Resistance of Inductance Coils at Radio Frequency", Wireless and Wireless Eng., 3: 483

- Hansen, Peder M.; Gish, Darrell (February 1995), "WWVB Antenna and Antenna Tuning System: Baseline Measurements" (PDF), Naval Command, Control and Ocean Surveillance Center, Technical Report 1693, also available as DTIC ADA299078., possibly also available as .

- Sullivan, Charles R. (March 1999), "Optimal Choice for Number of Strands in a Litz-Wire Transformer Winding" (PDF), IEEE Transactions on Power Electronics, 14 (2): 283–291, doi:10.1109/63.750181

- Terman, Frederick E. (1943), Radio Engineers' Handbook, McGraw-Hill, pp. 37, 74, 80

External links

| Wikimedia Commons has media related to Litz wire. |

- New England Wire Technologies - Litz Wire (free technical support)

- The litz people at HSM Wire offer a lot of information and support related to litz wire

- Manfred Albach, Janina Patz, Hans Rossmanith, Dietmar Exner, Alexander Stadler: Optimized Winding = Optimum in Power Efficiency, Comparison of Losses in litz wires and round wires, The original text was released in the german magazine Elektronik Power, April 2010, Page 38-77

- NAA Cutler Maine - Navy VLF Transmitter Site: 2 MW, 14-24 kc. Naval transmitter uses 4-inch diameter Litz wire; picture of variometer.