Push–pull strategy

The business terms push and pull originated in logistics and supply chain management,[2] but are also widely used in marketing,[3][4] and is also a term widely used in the hotel distribution business. Wal-Mart is an example of a company that uses the push vs. pull strategy. A push–pull system in business describes the movement of a product or information between two subjects. On markets the consumers usually "pull" the goods or information they demand for their needs, while the offerers or suppliers "push" them toward the consumers. In logistics chains or supply chains the stages are operating normally both in push- and pull-manner.[5] Push production is based on forecast demand and pull production is based on actual or consumed demand. The interface between these stages is called the push–pull boundary or decoupling point.[5]

Supply-Chain Management

Complete Definition

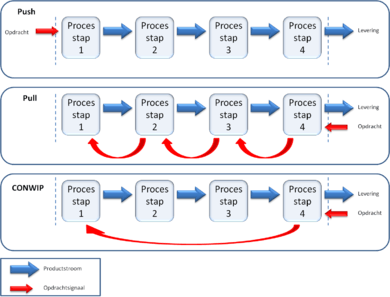

- PUSH – Node performs order planning for succeeding node. Like stated by Bonney et al. (1999) control information flow is in the same direction of goods flow.

- SEMI PUSH or PUSH-PULL – Succeeding node makes order request for preceding node. Preceding node reacts by replenishing from stock that is rebuilt every fixed period.

- PULL – Succeeding node makes order request for preceding node. Preceding node reacts by producing the order, which involves all internal operations, and replenishes when finished.

- SEMI-PULL or PULL-PUSH – Succeeding node makes order request for preceding node. Preceding node reacts by replenishing from stock that is rebuilt immediately. Note that there are several levels of semi-pull systems as the node can have stock at several layers in the organization.[6]

Information flow

With a push-based supply chain, products are pushed through the channel, from the production side up to the retailer. The manufacturer sets production at a level in accord with historical ordering patterns from retailers. It takes longer for a push-based supply chain to respond to changes in demand, which can result in overstocking or bottlenecks and delays (the bullwhip effect), unacceptable service levels and product obsolescence.

In a pull-based supply chain, procurement, production and distribution are demand-driven rather than to forecast. However, a pull strategy does not always require make-to-order production. Toyota Motors Manufacturing is frequently used as an example of pull production, yet do not typically produce to order. They follow the "supermarket model" where limited inventory is kept on hand and is replenished as it is consumed. In Toyota's case, Kanban cards are used to signal the need to replenish inventory.

A supply chain is almost always a combination of both push and pull, where the interface between the push-based stages and the pull-based stages is sometimes known as the push–pull boundary.[5] However, because of the subtle difference between pull production and make-to-order production a more accurate name for this may be the decoupling point. An example of this would be Dell's build to order supply chain. Inventory levels of individual components are determined by forecasting general demand, but final assembly is in response to a specific customer request. The decoupling point would then be at the beginning of the assembly line.

Depending on the medium used, the communication can be either interactive or non-interactive. For example, if the seller makes his promotion by television or radio, it's not possible for the buyer to interact. On the other hand, if the communication is made by phone or internet, the buyer has possibilities to interact with the seller. In the first case information is just "pushed" toward the buyer, while in the second case it is possible for the buyer to demand the needed information according to their requirements.

- Applied to that portion of the supply chain where demand uncertainty is relatively small

- Production and distribution decisions are based on long term forecasts

- Based on past orders received from retailer's warehouse (may lead to Bullwhip effect)

- Inability to meet changing demand patterns

- Large and variable production batches

- Unacceptable service levels

- Excessive inventories due to the need for large safety stocks

- Less expenditure on advertising than pull strategy...

In a marketing "pull" system, the consumer requests the product and "pulls" it through the delivery channel. An example of this is the car manufacturing company Ford Australia. Ford Australia only produces cars when they have been ordered by the customers.

- Applied to that portion of the supply chain where demand uncertainty is high

- Production and distribution are demand driven

- No inventory, response to specific orders

- Point of sale (POS) data comes in handy when shared with supply chain partners

- Decrease in lead time

- Difficult to implement

When to use Pull/Push/Hybrid Push-Pull strategy

Harrison summarized when to use each one of the three supply chain strategies:

- Push based supply chain strategy, usually suggested for products with small demand uncertainty, as the forecast will provide a good direction on what to produce and keep in inventory, and also for products with high importance of economies of scale in reducing costs.

- Pull based supply chain strategy, usually suggested for products with high demand uncertainty and with low importance of economies of scales, which means, aggregation does not reduce cost, and hence, the firm would be willing to manage the supply chain based on realized demand.

- Hybrid Push–Pull strategy, usually suggested for products which uncertainty in demand is high, while economies of scale are important in reducing production and/or delivery costs. One good example of this strategy is the furniture industry, where production strategy has to follow a Pull-based strategy, since it is impossible to make production decisions based on long-term forecasts. On the other hand, the distribution strategy needs to take advantage of economies of scale in order to reduce transportation cost, using a Push-based strategy.[5]

Examples in Push and Pull

Hopp and Spearman consider some of the most common systems found in industry and the literature and classify them as either push or pull.

- MRP (Materials Requirement Planning) is a push system because releases are made according to a master production schedule without regard to system status. Hence, no a priori WIP limit exists.

- Classic kanban is a pull system. The number of kanban cards establishes a fixed limit on WIP.

- Classic Base Stock System is, somewhat surprisingly, a push system because there is no limit on the amount of work in process in the system. This is because backorders can increase beyond the basestock level.

- Installation stock (Q, r) is also a push system as are echelon stock (Q, r) systems because neither imposes a limit on the number of orders in the system.

- CONWIP is a pull system because it limits WIP via cards similar to kanban. An important difference from kanban from an implementation standpoint is that the cards are line specific rather than part number specific. However, from a push/pull perspective, CONWIP cards limit WIP in the same manner as kanban cards.

- (K, S) systems (proposed by Liberopoulos and Dallery) are pull systems if K <∞ and are push systems otherwise.

- POLCA systems proposed by Suri is a pull system because, like kanban and CONWIP, WIP is limited by cards.

- PAC systems proposed by Buzacott and Shanthikumar is a pull system when the number of process tags (which serve to limit WIP) is less than infinity.

- MRP with a WIP constraint (as suggested by Axsäter and Rosling) is a pull system.[7]

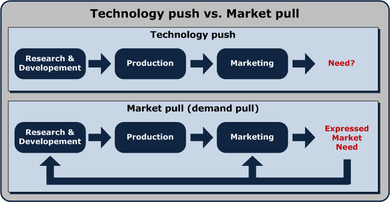

Marketing

An advertising push strategy refers to a situation when a vendor advertises its product to gain audience awareness, while the pull strategy implies the aims to reach audiences which have shown existing interest in the product or information about it. The difference between "push" and "pull" marketing can also be identified by the manner in which the company approaches the lead. If, for example, the company were to send a sales brochure, that would be considered pushing the opportunity toward the lead. If, instead, the company provided a subject matter expert as a speaker for an industry event attended by targeted leads, that could be one tactic used as part of a strategy to pull in a lead by encouraging that lead to seek out the expert in a moment of need for that expertise.

Hotel Distribution

The online world has brought this pull push decision to the hotel distribution business arena

- Push strategies in the hotel distribution business imply that hotel inventory is placed for the distributors or resellers outside the hotel system in one or several extranets that belong to these distributors (Online Travel Agencies, Touroperators, Bed Banks). The inventory must be therefore updated in these extranets. The hotel servers receive less traffic preventing server crashes but booking must be transferred to the hotel system.

- Pull strategies on the contrary are based on the distributors interfacing with the Hotel Property Management System. In this case the inventory is "pulled" from the hotel (or hotel chain) system. This method provides a much more precise picture of the real availability and saves time loading the bookings but, requires more IT development and a bigger server (dedicated one).

Push–pull music marketing future

Many media and music futurists have observed large changes within the music industry and predict larger ones to come. The introduction and success of social networking, along with the rise of digital music, has transformed the way music is marketed to the consumer; shifting from a push to pull strategy. The prior push strategy would feature a marketing campaign in total control of the message being sent out. The newer pull strategy has been viewed as a shift in power from advertisers to consumers, and so requires a more adaptive approach by marketers.

With the increase of social networking platforms and users, social networking has become a major and focal part to music marketing adopting the pull marketing strategy. Pull marketing shifts the emphasis and attention onto the customer, trying to market in the correct places by knowing who the target audience is. Consumers are increasingly customizing to better suit their individual needs. Rather than relying on music companies or a DJ to pre-determine the mix of songs on a CD, an increasing number of music listeners are downloading individual tracks and assembling their own sequence of songs. This process is also being replicated with the creation of playlists through platforms such as iTunes, Spotify and Last FM. Fan-built playlists and mixes are taking over the way people get their music. Playlists are inevitably becoming a pull marketing resource that marketing alliances must embrace, due to their ability to be shared via Peer to peer networks. People are choosing what they want to hear rather than having it pushed on them.

As consumers gain access to a greater number of options and platforms, and more information about such services, the consumer will probably become more demanding on resource providers, requiring services to be made available on consumers terms, rather than when it is convenient for the resource providers to deliver them. In addition, consumers are demanding the ability to configure their own products from resource providers, leading to rapid growth in options and music services. To thrive in a broad market, digital music services attempt different models and features to find the optimum mix and ensure consumer satisfaction.

See also

References

- ↑ Martin, Michael J.C. (1994). Managing Innovation and Entrepreneurship in Technology-based Firms. Wiley-IEEE. p. 44. ISBN 0-471-57219-5.

- ↑ Edward G. Hinkelman & Sibylla Putzi (2005). Dictionary of International Trade – Handbook of the Global Trade Community. World Trade Press. ISBN 1-885073-72-0.

- ↑ Peter, J. Paul; James H. Donnelly (2002). A Preface to Marketing Management. McGraw-Hill Professional. p. 132. ISBN 0-07-246658-8.

- ↑ Dowling, Grahame Robert (2004). The Art and Science of Marketing. Oxford University Press. p. 266. ISBN 0-19-926961-0.

- 1 2 3 4 Terry P. Harrison, Hau L. Lee and John J. Neale (2003). The Practice of Supply Chain Management. Springer. ISBN 0-387-24099-3.

- ↑ J., Ashayeri; R.P., Kampstra (2005). "Demand Driven Distribution: The Logistical Challenges and Opportunities" (Department of Econometrics and Operations Research Tilburg University).

- ↑ Hopp, Wallace J.; Spearman, Mark L. "To pull or not to pull: what is the question?". Manuf Serv Oper Manage. Retrieved 13 June 2014.