VVER

The Water-Water Energetic Reactor (VVER),[1] or WWER (from Russian: Водо-водяной энергетический реактор; transliterates as Vodo-Vodyanoi Energetichesky Reaktor; Water-Water Power Reactor) is a series of pressurised water reactor designs originally developed in the Soviet Union, and now Russia, by OKB Gidropress.[2] Power output ranges from 70 to 1200 MWe, with designs of up to 1700 MWe in development.[3] VVER power stations were, are or will be used by Armenia, Bangladesh, Belarus, Bulgaria, China, Czech Republic, Egypt, Finland, Germany, Jordan, Hungary, India, Iran, Slovakia, Ukraine, Russia and Vietnam.

History

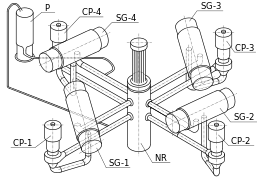

The earliest VVERs were built before 1970. The VVER-440 Model V230 was the most common design, delivering 440 MW of electrical power. The V230 employs six primary coolant loops each with a horizontal steam generator. A modified version of VVER-440, Model V213, was a product of the first nuclear safety standards adopted by Soviet designers. This model includes added emergency core cooling and auxiliary feedwater systems as well as upgraded accident localization systems.[4]

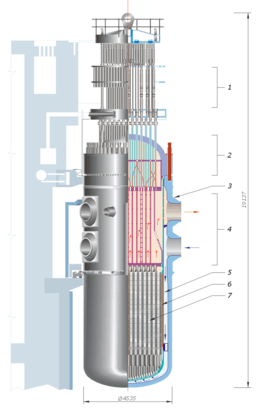

The larger VVER-1000 was developed after 1975 and is a four-loop system housed in a containment-type structure with a spray steam suppression system. VVER reactor designs have been elaborated to incorporate automatic control, passive safety and containment systems associated with Western third generation nuclear reactors.

The VVER-1200 is the version currently offered for construction, being an evolution of the VVER-1000 with increased power output to about 1200 MWe (gross) and providing additional passive safety features.[5]

In 2012, Rosatom stated that in the future it intended to certify the VVER with the British and U.S. regulatory authorities, though was unlikely to apply for a British licence before 2015.[6][7]

Design

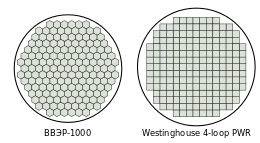

The Russian abbreviation VVER stands for 'water-water energy reactor' (i.e. water-cooled water-moderated energy reactor). The design is a type of pressurised water reactor (PWR). The main distinguishing features of the VVER[3] compared to other PWRs are:

- Horizontal steam generators

- Hexagonal fuel assemblies

- No bottom penetrations in the pressure vessel

- High-capacity pressurisers providing a large reactor coolant inventory

Reactor fuel rods are fully immersed in water kept at 15 MPa pressure so that it does not boil at the normal (220 to over 300 C) operating temperatures. Water in the reactor serves both as a coolant and a moderator which is an important safety feature. Should coolant circulation fail, the neutron moderation effect of the water diminishes, reducing reaction intensity and compensating for loss of cooling, a condition known as negative void coefficient. Later versions of the reactors are encased in massive steel pressure shells. Fuel is low enriched (ca. 2.4–4.4% 235U) uranium dioxide (UO2) or equivalent pressed into pellets and assembled into fuel rods.

Reactivity is controlled by control rods that can be inserted into the reactor from above. These rods are made from a neutron absorbing material and, depending on depth of insertion, hinder the chain reaction. If there is an emergency, a reactor shutdown can be performed by full insertion of the control rods into the core.

Primary cooling circuits

As stated above, the water in the primary circuits is kept under a constant elevated pressure to avoid its boiling. Since the water transfers all the heat from the core and is irradiated, the integrity of this circuit is crucial. Four main components can be distinguished:

- Reactor vessel: Water flows through the fuel rod assemblies which are heated by the nuclear chain reaction.

- Volume compensator (Pressurizer): To keep the water under constant but controlled pressure, the volume compensator regulates the pressure by controlling the equilibrium between saturated steam and water using electrical heating and relief valves.

- Steam Generator: In the steam generator, the heat from the primary coolant water is used to boil the water in the secondary circuit.

- Pump: The pump ensures the proper circulation of the water through the circuit.

To provide for the continued cooling of the reactor core in emergency situations the primary cooling is designed with redundancy.

Secondary circuit and electrical output

The secondary circuit also consists of different subsystems:

- Steam Generator: Secondary water is boiled taking heat from the primary circuit. Before entering the turbine remaining water is separated from the steam so that the steam is dry.

- Turbine: The expanding steam drives a turbine, which connects to an electrical generator. The turbine is split into high and low pressure sections. To prevent condensation (Water droplets at high speed damage the turbine blades) steam is reheated between these sections. Reactors of the VVER-1000 type deliver 1 GW of electrical power.

- Condenser: The steam is cooled and allowed to condense, shedding waste heat into a cooling circuit.

- Deaerator: Removes gases from the coolant.

- Pump: The circulation pumps are each driven by their own small steam turbine.

To increase efficiency of the process, steam from the turbine is taken to reheat coolant before the deaerator and the steam generator. Water in this circuit is not supposed to be radioactive.

Tertiary cooling circuit

The tertiary cooling circuit is an open circuit diverting water from an outside reservoir such as a lake or river. Evaporative cooling towers, cooling basins or ponds transfer the waste heat from the generation circuit it into the environment. In most VVERs this heat can also be further used for residential and industrial heating. Operational examples of such systems are the plants at Jaslovské Bohunice and Dukovany. [8]

Safety barriers

A typical design feature of nuclear reactors is layered safety barriers preventing escape of radioactive material. VVER reactors have four layers:

- Fuel pellets: Radioactive elements are retained within the crystal structure of the fuel pellets.

- Fuel rods: The zircaloy tubes provide a further barrier resistant to heat and high pressure.

- Reactor Shell: A massive steel shell encases the whole fuel assembly hermetically.

- Reactor Building: A concrete containment building that encases the whole first circuit is strong enough to resist the pressure surge a breach in the first circuit would cause.

Compared to the RBMK reactors – the type involved in the Chernobyl disaster – the VVER uses an inherently safer design. It does not have the graphite-moderated RBMK's risk of a power surge transient or criticality accident. Also the RBMK power stations were constructed without containment structures on grounds of cost as well as the relative ease of re-fueling. (Fuel elements in an RBMK can be replaced while the reactor is running at its nominal output, allowing the continuous operation and plutonium extraction compared to pressurized water reactors like the VVER which need to be shut down to exchange fuel rod assemblies.)

Operational life of VVER 1000

When first built the VVER design was intended to be operational for 35 years. A mid-life major overhaul including a complete replacement of critical parts such as fuel and control rod channels was thought necessary after that.[9] Since RBMK reactors specified a major replacement programme at 35 years designers originally decided this needed to happen in the VVER type as well, although they are of more robust design than the RBMK type. Most of Russia's VVER plants are now reaching and passing the 35 year mark. More recent design studies have allowed for an extension of lifetime up to 50 years with replacement of equipment. New VVERs will be nameplated with the extended lifetime.

In 2010 the oldest VVER-1000, at Novovoronezh, was shut down for modernization to extend its operating life for an additional 30 years; the first to undergo such an operating life extension. The work includes the modernization of management, protection and emergency systems, and improvement of security and radiation safety systems.[10]

VVER-1200

The VVER-1200 (or NPP-2006 or AES-2006)[5] is an evolution of the VVER-1000 being offered for domestic and export use.[11][12] The reactor design has been refined to optimize fuel efficiency. Specifications include a $1,200 per kW electric capital cost, 54 month planned construction time, and expected 60 year lifetime at 90% capacity factor. The VVER 1200 will produce 1,200 MWe of power.

The first two units are being built at Leningrad Nuclear Power Plant II and Novovoronezh Nuclear Power Plant II. More reactors with a VVER-1200/491 like the Leningrad-II-design are planned (Kaliningrad and Nizhny Novgorod NPP) and under construction. The type VVER-1200/392M[13] as installed at the Novovoronezh NPP-II has also been selected for the Seversk, Zentral and South-Urals NPP. A standard version was developed as VVER-1200/513 and based on the VVER-TOI (VVER-1300/510) design.

In July 2012 a contract was agreed to build two AES-2006 in Belarus at Ostrovets for a cost of about $10 billion (Note that this price equates to $4,200 per kW capital cost as opposed to the $1,200 per kW initially cited above).[14] An AES-2006 is being bid for the Hanhikivi Nuclear Power Plant in Finland.[15]

In August 2016 the first VVER-1200, Novovoronezh II-1, was connected to the grid.[16]

Safety features

The nuclear part of the plant is housed in a single building acting as containment and missile shield. Besides the reactor and steam generators this includes an improved refueling machine, and the computerized reactor control systems. Likewise protected in the same building are the emergency systems, including an emergency core cooling system, emergency backup diesel power supply, and backup feed water supply,

A passive heat removal system had been added to the existing active systems in the AES-92 version of the VVER-1000 used for the Kudankulam Nuclear Power Plant in India. This has been retained for the newer VVER-1200 and future designs. The system is based on a cooling system and water tanks built on top of the containment dome.[17] The passive systems handle all safety functions for 24 hours, and core safety for 72 hours.[5]

Other new safety systems include aircraft crash protection and a core catcher to contain the molten reactor core in the event of a severe accident.[12][14]

Future versions

A number of designs for future versions of the VVER have been made:[18]

- MIR-1200 (Modernised International Reactor) - designed in conjunction with Czech company ŠKODA JS[19] to satisfy European requirements[20]

- VVER-1500 - VVER-1000 with dimensions increased to produce 1500 MWe gross power output, but design shelved in favour of the evolutionary VVER-1200[21]

- VVER-TOI is aimed at development of typical optimized informative-advanced project of a new generation III+ Power Unit based on VVER technology, which meets a number of target-oriented parameters using modern information and management technologies.[22]

- VVER-1700 Supercritical water reactor version.

- VVER-600 two cooling circuit version of the VVER-1200 designed for smaller markets, authorised to be built by 2030 at the Kola Nuclear Power Plant.[23][24]

Power plants

| Power plant | Country | Reactors | Notes |

|---|---|---|---|

| Akkuyu | Turkey | (4 × VVER-1200/513) (AES-2006 with TOI-Standard) | Construction start expected for 2016. |

| Balakovo | Russia | 4 × VVER-1000/320 (2 × VVER-1000/320) | Unit 5 and 6 construction suspended. |

| Belene | Bulgaria | (2 × VVER-1000/466B) | Suspended.[25] |

| Bohunice | Slovakia | 2 × VVER-440/230 2 × VVER-440/213 | Split in two plants, V-1 and V-2 with two reactors each. VVER-440/230 units at V-1 plant decommissioned in 2006 and 2008. |

| Bushehr | Iran | 1 × VVER-1000/446 (3 × VVER-1000/446) | A version of the V-320 adapted to the Bushehr site.[26] Unit 2 and 3 planned, unit 4 cancelled. |

| Dukovany | Czech Republic | 4 × VVER 440/213 | Now upgraded to 502 MW in 2009-2012. |

| Greifswald | Germany | 4 × VVER-440/230 1 × VVER-440/213 (3 × VVER-440/213) | Decommissioned. Unit 6 finished, but never operated. Unit 7 and 8 construction suspended. |

| Kalinin | Russia | 2 × VVER-1000/338 2 × VVER-1000/320 | Unit 4 operational 2011. |

| Hanhikivi | Finland | 1 × VVER-1200/491 | Planned,[27] operational 2024. |

| Khmelnitskiy | Ukraine | 2 × VVER-1000/320 (2 × VVER-1000/392B) | Unit 3 and 4 under construction. |

| Kola | Russia | 2 × VVER-440/230 2 × VVER-440/213 | |

| Koodankulam | India | 1 × VVER-1000/412 (AES-92) (1 × VVER-1000/412) (AES-92) | Unit 1 operational since 13 July 2013 and Unit operational since 10 July 2016.[28] 2 additional Units planned. |

| Kozloduy | Bulgaria | 4 × VVER-440/230 2 × VVER-1000 | VVER-440/230 units decommissioned 2004-2007. |

| Leningrad II | Russia | 2 × VVER-1200/491 (2 × VVER-1200/491) | The units are the prototypes of the VVER-1200/491 (AES-2006) and under construction. |

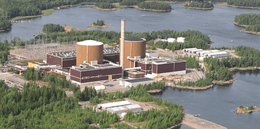

| Loviisa | Finland | 2 × VVER-440/213 | Western control systems, Totally different containment structures. Later modified for a 496 MW output. |

| Metsamor | Armenia | 2 × VVER-440/270 | One reactor was shut down in 1989. |

| Mochovce | Slovakia | 2 × VVER-440/213 (2 × VVER-440/213) | Units 3 and 4 under construction, planned to be operational between 2018 and 2019. |

| Novovoronezh | Russia | 1 x VVER-210 (V-1) 1 x VVER-365 (V-3M) 2 × VVER-440/179 1 × VVER-1000/187 | All units are prototypes. Unit 1 and 2 shutdown. Unit 3 modernised in 2002.[29] |

| Novovoronezh II | Russia | (2 × VVER-1200/392M) (AES-2006) | The units are the prototypes of the VVER-1200/392M (AES-2006) and under construction. |

| Paks | Hungary | 4 × VVER-440/213 | Two VVER-1200 units planned |

| Rheinsberg | Germany | 1 × VVER-70 (V-2) | Unit decommissioned |

| Rivne | Ukraine | 2 × VVER-440/213 2 × VVER-1000/320 (2 × VVER-1000/320) | Unit 5 and 6 planning suspended. |

| South Ukraine | Ukraine | 1 × VVER-1000/302 1 × VVER-1000/338 1 × VVER-1000/320 (1 × VVER-1000/320) | unit 4 construction suspended. |

| Stendal | Germany | (4 × VVER-1000/320) | All 4 units construction cancelled after Germany reunification. |

| Temelin | Czech Republic | 2 × VVER-1000/320 | |

| Tianwan | China | 2 × VVER-1000/428 (AES-91) (6 × VVER-1000/428M) | Unit 3 to 8 firmly planned. |

| Volgodonsk (Rostov) | Russia | 3 × VVER-1000/320 (1 × VVER-1000/320) |

Unit 4 is under construction and planned to be operational in 2017. |

| Zaporizhzhia | Ukraine | 6 × VVER-1000/320 | Largest nuclear power plant in Europe. |

- See the Wikipedia pages for each facility for sources.

Russia recently installed two nuclear reactors in China at the Tianwan Nuclear Power Plant, and an extension consisting of a further two reactors was just approved. This is the first time the two countries have co-operated on a nuclear power project. The reactors are the VVER 1000 type, which Russia has improved incrementally while retaining the basic design. These VVER 1000 reactors are housed in a confinement shell capable of being hit by an aircraft weighing 20 tonnes and suffering no expected damage. Other important safety features include an emergency core cooling system and core confinement system. Russia delivered initial fuel loads for the Tianwan reactors. China planned to begin indigenous fuel fabrication for the Tianwan plant in 2010, using technology transferred from Russian nuclear fuel producer TVEL.[30]

The Tianwan Nuclear Power Plant uses many third party parts. While the reactor and turbo-generators are of Russian design, the control room was designed and built by an international consortium. In this way the plant was brought to meet widely recognised safety standards; safety systems were already mostly in place but the previous monitoring of these systems did not meet international safety standards. The new VVER 1000 plant built in China has 94% of its systems automated, meaning the plant can control itself under most situations. Refueling procedures require little human intervention. Five operators are still needed in the control room. The IAEA has referred to the station as the "safest nuclear power plant in the world".[31]

In May 2010 Russia secured an agreement with the Turkish government to build a power plant with four VVER-1200 reactors at Akkuyu, Turkey.[32][33] However, due to the accident experienced in Fukushima, anti-nuclear environmentalist groups heavily protested the proposed reactor at Akkuyu.

On 11 October 2011 an agreement was signed to build Belarus’ first nuclear power plant at Astravyets, using two NPP-2006 reactors with active and passive safety systems. The first unit is planned to be completed by 2017.[34]

In October 2013 the VVER-1000 (AES-92) design was selected by the Jordan Atomic Energy Commissionin a competitive tender for Jordan's first twin reactor nuclear power station.[35]

See also

References

- ↑ "Kudankulam nuclear plant starts generating power, connected to southern grid". The Times Of India.

- ↑ "Historical notes". OKB Gidropress. Retrieved 20 September 2011.

- 1 2 "WWER-type reactor plants". OKB Gidropress. Retrieved 25 April 2013.

- ↑ Prof. H. Böck. "WWER/ VVER (Soviet designed Pressurized Water Reactors)" (PDF). Vienna University of Technology. Austria Atominstitute. Retrieved 28 September 2011.

- 1 2 3 Fil, Nikolay (26–28 July 2011). "Status and perspectives of VVER Status and perspectives of VVER nuclear power plants nuclear power plants" (PDF). OKB Gidropress. IAEA. Retrieved 28 September 2011.

- ↑ "Rosatom Intends to Certify VVER in Great Britain and USA". Novostienergetiki.re. 6 June 2012. Retrieved 21 June 2012.

- ↑ Svetlana Burmistrova (13 August 2013). "Russia's Rosatom eyes nuclear contracts in Britain". Reuters. Retrieved 14 August 2013.

- ↑ Cogeneration in the Former Soviet Union; June 24 1997

- ↑ Martti Antila, Tuukka Lalitinen. "Recent Core Design and Operating Experience in Loviisa NPP" (PDF). Fortum Nuclear Services Ltd, Espoo, Finland. IAEA. Retrieved 20 September 2011.

- ↑ "Modernization works begin at Russia's oldest VVER-1000". Nuclear Engineering International. 30 September 2010. Retrieved 10 October 2010.

- ↑ "AES-2006 (VVER-1200)". Rosatom. Retrieved 22 September 2011.

- 1 2 Asmolov, V. G. (10 September 2009). "Development of the NPP Designs Based on the VVER Technology" (PDF). Rosatom. Retrieved 9 August 2012.

- ↑ "WWER-1000 reactor plant (V-392)". OKB Gidropress. Retrieved 22 September 2011.

- 1 2 "$10 billion construction contract signed for two AES 2006 Russian reactors in Belarus". I-Nuclear. 19 July 2012. Retrieved 8 August 2012.

- ↑ "Rosatom buys into Fennovoima". World Nuclear News. 28 March 2014. Retrieved 29 March 2014.

- ↑ "Russia connects Novovoronezh 6 reactor to grid". World Nuclear News. 5 August 2016. Retrieved 17 September 2016.

- ↑ V.G. Asmolov (26 August 2011). "Passive safety in VVERs". JSC Rosenergoatom. Nuclear Engineering International. Retrieved 6 September 2011.

- ↑ "Advanced Nuclear Power Reactors". World Nuclear Association. September 2011. Retrieved 22 September 2011.

- ↑ "MIR.1200". ŠKODA JS. Retrieved 23 September 2011.

- ↑ "MIR-1200". OKB Gidropress. Retrieved 22 September 2011.

- ↑ "WWER-1500 reactor plant". OKB Gidropress. Retrieved 22 September 2011.

- ↑ "Создание типового проекта оптимизированного и информатизированного энергоблока технологии ВВЭР (ВВЭР-ТОИ)". Rosatom Nuclear Energy State Corporation.

- ↑ Status report 102 - VVE R-600 (V-498) (VVER-600 (V-498)) (PDF) (Report). IAEA. 22 July 2011. Retrieved 17 September 2016.

- ↑ "Russia to build 11 new nuclear reactors by 2030". World Nuclear News. 10 August 2016. Retrieved 17 September 2016.

- ↑ "Bulgarian Parliament Votes to Abandon Belene Nuclear Plant". worldnuclearreport.org. 27 Feb 2013. Retrieved 22 Sep 2014.

- ↑ Anton Khlopkov and Anna Lutkova (21 August 2010). "The Bushehr NPP: Why did it take so long" (PDF). Center for Energy and Security Studies. Retrieved 1 March 2011.

- ↑ http://www.world-nuclear.org/info/Country-Profiles/Countries-A-F/Finland/

- ↑ Kudankulam Nuclear Power Plant attains criticality

- ↑ "New life of Novovoronezh 3". Nuclear Engineering International. 3 June 2002. Retrieved 9 March 2011.

- ↑ Tianwan fuel fabrication moves to China; March 2010

- ↑ Russian-Chinese nuclear station safest in the world: IAEA, RussiaToday, 2007-12-07

- ↑ "Arrangements Completed for Nuclear Power Plant". Turkish Weekly. 15 August 2011.

- ↑ "Генплан размещения первой турецкой АЭС разработают осенью 2011 года (Master plan of placing the first Turkish nuclear power plant will develop a fall 2011)". Ria Novosti. 22 August 2011. Source for "четырех энергоблоков с реакторами ВВЭР-1200 по российскому" or "four VVER-1200 reactors"

- ↑ "Russia signs up to build NPP in Belarus". Nuclear Engineering International. 20 October 2011. Retrieved 24 October 2011.

- ↑ "Jordan selects its nuclear technology". World Nuclear News. 29 October 2013. Retrieved 2 November 2013.

External links

- WWER-type reactor plants, OKB Gidropress.

- AES-2006 (VVER-1200), Rosatom.

- VVER Reactor at Virtual Nuclear Tourist.