Cottam power stations

| Cottam power station | |

|---|---|

The power station, viewed from the north. July 2006. | |

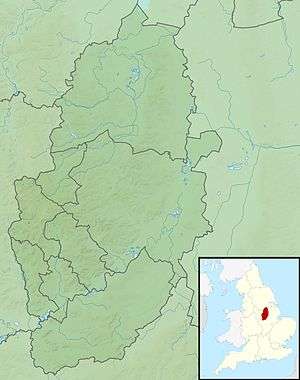

Location of Cottam power station in Nottinghamshire | |

| Country | England |

| Location | Cottam |

| Coordinates | 53°18′14″N 0°46′53″W / 53.304°N 0.7815°WCoordinates: 53°18′14″N 0°46′53″W / 53.304°N 0.7815°W |

| Status | Operational |

| Operator(s) |

Central Electricity Generating Board (1969-1990) Powergen (1990-2000) London Energy (2000-present) |

| Thermal power station | |

| Primary fuel | Coal |

| Secondary fuel | Oil |

| Tertiary fuel | Biomass |

| Power generation | |

| Units operational | 4 |

| Make and model | English Electric Co. Ltd. |

| Nameplate capacity | 2,000 MW |

| grid reference NZ174644 | |

The Cottam power stations are a pair of power stations, the site extends some 620 acres of mainly arable land and is situated within and adjacent to the eastern boundary of Nottinghamshire on the west bank of the River Trent at Cottam near Retford in Nottinghamshire. The larger of the two is a coal-fired power station, which was commissioned in 1969 by the Central Electricity Generating Board, and has a generating capacity of 2,000 megawatts (MW). It is now owned by EDF Energy.[1] The other is Cottam Development Centre, a combined cycle gas turbine plant commissioned in 1999, with a generating capacity of 400 MW. This plant is owned by E.ON UK.

The site is one of a number of power stations located along the Trent valley, with the West Burton power stations located 3.5 miles (5.6 km) downstream of the station, and Ratcliffe-on-Soar power station located 52 miles (84 km) upstream. The decommissioned High Marnham Power Station is located 6 miles (9.7 km) upstream.

Construction

Work commenced on site in April 1964 on the site of the old Mickleholme Farm by the Central Electricity Generating Board Midlands Region from Bournville. The ground level before construction varied between 3.35m and 5.18m (11 and 17 ft) ordnance datum (O.D.) In order to provide adequate protection against flooding, the area in which the main building is constructed was raised to 7.92m (26 ft) O.D. by filling from borrow pits on site, whilst the coal store and cooling tower area remain at the original level of 4.87m (16 ft) O.D. The nature of the sub-soil was investigated by trial bores and found to be good load bearing marl at depths between 4.26m and 12.19m (14 and 40 ft) below the existing ground level and overlain by sand and gravel strata on top of which lay clay or silt and top soil.

The main building which is 209.39m (687 ft) long by 124.35m (408 ft) wide houses four 500 MW boiler-turbine units. The height of the boiler house is 65.22m (214 ft) and turbine house 34.44m (113 ft). The building is of steel construction with blockwork up to 10.66m (35 ft), above which there is a light-weight corrugated sheet cladding and windows.

An interesting feature of the construction of this building was the way in which the civil and steel erection work was phased. By completing the pile caps on Nos. q and 2 units, the steel erection work was able to progress, whilst pile caps and flooring were completed on Nos. 3 and 4 units. This enabled the steel work to be erected on Nos. 3 and 4 units from finished floor level whilst the flooring was being completed on Nos. 1 and 2 units. The result was a reduction in overall time to construct the main building.

Within the boiler house and between Nos. 2 and 3 boilers, an escalator was erected which in several stages extended to the boiler drum level to assist with the movement of men and materials. To the north of the main building is the precipitator bay and chimney. The four flues from the boiler are contained within a single chimney which stands 190.5m (625 ft) above ground level. In order to improve on plume dispersal, the outer chimney casing is terminated 7.62m (25 ft) short of the four flues which stand at a height of 198.12m (650 ft)

To the east of the main building are eight cooling towers which are 114.3m (375 ft) in height and have a base diameter of 94.48m (310 ft) overall. Beyond this are the coal plant and the coal stocking area. The 400kV switching station is to the south of the site from which feeders join the National Grid system by way of other substations in the area. To the west are the station workshops and administration block of offices, which are connected to the turbine house by an enclosed overhead walkway. Other associated buildings such as the control block, water treatment plant house, oil storage compound etc., are disposed around and adjacent to the main building.

Considerable attention has been paid to landscaping the site in order to improve the visual appearance of the large plant. The cladding of the main building is painted in “Cottam Amber” colour, which blends perfectly with the brickwork of houses and farms in the vicinity. Extensive grassing and tree planting was carried out on land around the site when all the construction work was finished.

The railway to the site reopened in 1967.[2] The power station opened in 1969 when owned by the Central Electricity Generating Board. The main contractor for the construction of the 2,000 MW power station was Balfour Beatty with the coal plant being supplied by the New Conveyor Company of Smethwick. The station has steam supplied to its English Electric 500 MW steam turbines by John Thompson boilers. The maximum continuous rating of the boiler is 2,400 lb/sq.in and 568 °C at the superheater. The modernist architects for the buildings on site were the Nottingham practice of Yorke Rosenberg Mardall. The station was originally commissioned with 4 x 25 MW gas generators in addition to the steam ones these consisted of 8 Rolls-Royce Avon RA29 Stage 6A (1533) engines (2 per set) these were later decommissioned on the arrival of the new CCGT installation. After electricity privatisation in 1990, ownership was shifted to Powergen. In October 2000, the plant was sold to London Energy, who are part of EDF Energy, for £398 million.[3]

Cottam Development Centre

The Cottam Development Centre is a 400 MW combined cycle gas turbine (CCGT) power station, fuelled by natural gas. It was built as a joint venture between Powergen and Siemens, as a testbed for Siemens to develop CCGT technology.

Construction of the station commenced in July 1997 on a football and cricket pitch adjacent to the coal-fired power station. During construction, heavy components weighing up to 400 tonnes were brought onto site using inland waterways, to avoid damaging local roads.[4] The station opened in September 1999. In May 2002 the station was bought out by Powergen for £52 million.

Specification

The power station generates electricity using a single Siemens V94.3A (now called a SGT5-4000F), which has one BENSON heat recovery steam generator gas turbine and one steam turbine.[5][6] Electricity from the station has a terminal voltage of 21 kilovolts (kV), and enters the National Grid via a transformer at 400 kV. The plant has a thermal efficiency of 58%.[4]

Industrial action

2004 Wildcat strike

Wildcat strike action was taken in December 2004, when scaffolding collapsed and injured one worker.[7]

2006 Wildcat strike

In February 2006, 51 British workers at the station walked out on Wildcat strike action due to the underpayment of Hungarian workers during construction of Flue Gas Desulphurisation equipment. The Hungarians had worse working conditions than the British workers and were underpaid £1 million by employer SFL. 15 British workers who walked out in solidarity were made redundant.[7]

References

- ↑ "Power Station Locations and Capacities". United Kingdom Quality Ash Association. Retrieved 6 February 2011.

- ↑ Modern Railways September 1966 p. 506

- ↑ "Powergen generates £398m from Cottam". The Telegraph. London. 17 October 2000. Retrieved 2 August 2008.

- 1 2 "Cottam Development Centre" (ASP). E.On UK. Retrieved 6 February 2011.

- ↑ "SGT5-4000F". Siemens. Retrieved 2 August 2008.

- ↑ "BENSON HRSG". Siemens. Retrieved 2 August 2008.

- 1 2 Steven (1 March 2006). "UK: Cottam power station wildcat strike". Retrieved 2 November 2009.

External links

| Wikimedia Commons has media related to Cottam Power Station. |