Improved Outer Tactical Vest

The Improved Outer Tactical Vest (IOTV), is an enhanced version of, and a replacement for, the older Outer Tactical Vest (OTV) variant of the Interceptor body armor, as fielded by the United States Army. The IOTV is compatible with the Deltoid and Auxiliary Protector System (DAPS) components, ESAPI (Enhanced Small Arms Protective Insert), Enhanced Side Ballistic Inserts (ESBI), as well as the OTV's groin protector.

The OTV design was considered insufficient and lacking in certain areas, which led to the IOTV's development and fielding. The IOTV is currently produced by Point Blank Body Armor, BAE Systems,[1] KDH Defense Systems,[2] Protective Products Enterprises,[3] UNICOR and Creative Apparel Associates. The IOTV first saw action in combat with U.S. Army ground combat units in late 2007/early 2008 and currently remains the standard body armor type used by regular U.S. Army ground combat units overseas.

Background

While the Interceptor body armor and the Outer Tactical Vest were considered fairly effective, questions were raised over whether or not they were the best possible armor solution for soldiers of the United States Military. This debate was heightened by controversy over Dragon Skin, produced by the now defunct Pinnacle Armor. Various claims surfaced that Dragon Skin was more effective at protecting soldiers than the then standard issue Interceptor body armor system, with independent studies and reports seeming to back these claims, eventually leading to multiple congressional members asking for further evaluation.[4] In response, the military made public testing that showed widespread failures in the testing of the Dragon Skin armor.[5] Ultimately, Dragon Skin never saw widespread adoption, and many of the perceived shortfalls of the Outer Tactical Vest such as standard of protection or modularity were addressed in the new Improved Outer Tactical Vest and E-SAPI plates.

Technical details

A size Medium IOTV weighs 33.6 pounds, less than a Medium OTV vest, while providing more coverage. However, a fully equipped IOTV, complete with all its components (soft armor panel inserts, four ballistic plate inserts (front and back plates and two side plates), collar, and groin protectors) still weighs 30 pounds (13.6 kg), with a Large IOTV weighing about 35 pounds (15.9 kg). The functionality of the enhanced side ballistic inserts, which provide coverage under the arms and down the sides of the torso, is built into the IOTV.

The IOTV provides the ability to don the vest in two ways. The first is to simply place the vest over the head and pull down, and the second is to remove fasteners on the wearer's left shoulder, sliding into the vest to the right. To complete the procedure for both methods the wearer then lifts up the front panel of the vest and fastens the waistband, which takes the weight of the vest off the shoulders somewhat, and then fastens the side protection modules.

A key design feature for the IOTV is that the entire armor system is able to be released with the pull of a hidden lanyard. The armor then falls apart into its component pieces, providing a means for escape in case the wearer falls into water or becomes trapped in a hazardous environment.[6] The hidden release lanyard also allows medical personnel easier access to a casualty, which was one concern that was not addressed with the old Interceptor armor.

It also features a grid of PALS webbing on the front, back, and sides for the attachment of modular pouches and accessories such as neck and throat protection, groin protection, or deltoid protection.[7]

Female Model

In response to the greater numbers of female soldiers in the Army, a female-specific version of the IOTV was developed. Previously, standard tactical vests were issued to women in combat. Soldiers found that women's movement was restricted, in ways such as bending over, getting in and out of tight spaces, or positioning their rifles against their shoulders. The long armor plates inside the vests would also rub against their hips and cut into their thighs when they sat down. Development of a model for women began in 2009. After much testing and measurements, the Army came up with a vest that is shorter to accommodate smaller torsos and has tailoring to fit closer to women’s chests. The new vest eliminates gaps between the material and the body and can be fitted with smaller side ballistic inserts for small waist sizes. The vest has a lighter feel because it doesn’t rest on the female soldier’s shoulders like the normal vest. The first female soldier vests were given to soldiers deploying for Afghanistan in September 2012.[8]

Features

Nearly all modern military body armor is designed to prevent penetration from bullets to vital areas of the body, in addition to protection against knives and fragmentation from explosives. Typically this is accomplished through both highly durable woven synthetic fibers such as Kevlar or Dyneema, and either metal or ceramic trauma plates. The IOTV is the standard issue torso protection component to the United States Army.

The IOTV is designed to take the weight of the vest off the shoulders and move it to the lower torso. The vest is also equipped with a mesh inner cover that is designed to improve airflow inside of the armor. There is also a back pad in the lower back area of the vest, which is designed to defeat fragmentation impacts to the lower back/kidney areas. However, the back pad does not provide significant ballistic protection. The vest can withstand a direct impact from a 7.62 millimeter (both NATO and ex-Soviet types) on the front or rear if using the older SAPI plates (NIJ standard III). Use of the new E-SAPI plates increase protection to armor-piercing versions of the aforementioned rounds in addition to .30-06 Springfield M2 armor-piercing rounds (NIJ standard IV). The IOTV provides, without the ballistic ceramic plates inserted, protection from small caliber rounds (i.e. 9mm) and fragmentation. The soft kevlar panels have been tested to stop 9 mm 124 grain full metal jacket bullets at 1,400 ft/s (426 m/s) with minimal deformation and has a V-50 of roughly 1,525 ft/s (465 m/s). This means that the bullet has to be traveling faster than 1,525 ft/s for it to have more than a 50% chance of breaking through the soft armor panel. These specifications are similar to the NIJ standard level III-A certification, however, military standards do not require their vests to be NIJ certified as this is primarily a law enforcement standard.

The modular design of the vest allows greater tactical flexibility in regards to different situations faced by ground troops. A US Army medical research report concluded that greater modular design leads to the ability to find a more effective balance between projectile protection and the physical endurance of the soldier, preventing losses in agility and mobility, and therefore reducing potential injuries or casualties.[9]

E-SAPI Plates

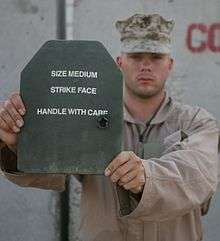

E-SAPI (Enhanced Small Arms Protective Insert) plates and their smaller counterparts E-SBI (Enhanced Side Ballistic Inserts) plates, are ceramic trauma plates that provide the bulk of the protection against projectiles when carried in an Improved Outer Tactical Vest, and are also used as part of many other body armors such as the Modular Tactical Vest. E-SAPI plates are designed to cover the vital front and back torso areas of the torso, while E-SBI plates are designed to protect the sides of the torso. The plate component itself is made of boron carbide, a widely used and extremely hard boron-carbon ceramic. Backing the plate is a layer of Spectra, a woven polymer material with extremely high tensile strength meant to stop any projectile that manages to pass through the ceramic strikeface.[10]

When a bullet strikes the E-SAPI plate, the kinetic energy is dispersed throughout the ceramic layer, and the majority of military rounds in common use are stopped or broken up. If the bullet continues through the boron carbide layer, the Spectra backing either stops the bullet, or, if the bullet was powerful enough, allows the bullet to pass through into the IOTV itself, and likely the wearer. Even in the event of the E-SAPI plate failing to prevent penetration, the velocity and energy of the penetrating round is oftentimes reduced to the point where the resulting wound is non lethal. E-SAPI plates are manufactured by Armorworks Enterprises, Ceradyne, Simula, and BAE Systems.[11]

Durability standards are high for E-SAPI plates, with Army requirements on environmental condition testing involving the plates being kept 6 hours at both a high temperature and a low temperature in addition to being dropped twice among a variety of other requirements. USSOCOM requirements are even more stringent, involving 24 hours at high and low temperatures.[12]

While E-SAPI plates do hold significant defensive advantages over the preceding SAPI plates, the increased protection comes at the cost of increased weight and significantly increased cost. Comparing medium-sized plates, a SAPI plate weighs 1.82 kilograms while an E-SAPI plate weighs 2.5 kilograms, over a 35 percent increase in weight.[13] In regards to cost, E-SAPI plates cost 50 percent more, coming in at approximately $600 per plate.[14] SAPI plates were largely phased out in favor of E-SAPI plates beginning in 2005.

Effectiveness

The Improved Outer Tactical Vest as a whole is a huge improvement over previous armor systems, with the fragmentation vest from the Vietnam war being limited to fragmentation protection, the PASGT vest being limited to pistol rounds, and the previous Outer Tactical Vest being unable to stop armor piercing rounds.

In response to the feedback of soldiers on the effectiveness of the armor system, the Army has continually upgraded the IOTV with new features, with Generation III involving a more intuitive quick release system and the new Operational Camouflage Pattern (OCP). Rather than producing entirely new IOTV armor sets, body armor conversion kits have been delivered at a lower cost in order to bring older Generation armor sets up to newer standards.[15]

Alternatives

One criticism carried over from the older OTV to the newer IOTV is what is regarded as the excessive weight of the armor, especially by dismounted infantrymen who regard the armor almost as a liability. In response to this, the US Army is looking into supplementing the heavy IOTV with the newer Modular Body Armor Vest (MBAV) and Soldier Plate Carrier System (SPCS) already in service in Ranger and Airborne units. The MBAV and SPCS do provide less soft body armor coverage, but are lighter than the IOTV, thus more suitable for patrol in Afghanistan.[16]

See also

- Interceptor body armor

- Modular Tactical Vest

- PRU-70

- Dragon Skin (body armor)

- Osprey body armour

- Soldier Plate Carrier System

- Body Armor

References

- ↑ "Improved Outer Tactical Vest | BAE Systems | United States". www.baesystems.com. Retrieved 2016-05-23.

- ↑ "KDH Defense | IOTV III – Improved Outer Tactical Vest (gen III)". www.kdhdefensesystems.com. Retrieved 2016-05-23.

- ↑ Protective Products Enterprises IOTV

- ↑ "Are U.S. soldiers wearing the best body armor?". msnbc.com. 2007-05-20. Retrieved 2016-05-23.

- ↑ "The Daily Nightly - MSNBC.com". dailynightly.msnbc.com. Retrieved 2016-05-23.

- ↑ Army to Field Improved Body Armor

- ↑ Harper, John. "Improved Outer Tactical Vest (IOTV)". Military.com. Retrieved 2016-05-13.

- ↑ Service, Donna Miles, American Forces Press. "Deploying Soldiers test new female body armor prototype | Article | The United States Army". www.army.mil. Retrieved 2016-05-23.

- ↑ Potter, Adam (2013-04-09). "Injury Control in the Military" (PDF). Defense Technical Information Center. US Army Research Institute of Environmental Medicine. Retrieved 2016-05-22.

- ↑ "Armor Piercing Myths". www.strategypage.com. Retrieved 2016-05-20.

- ↑ "ESAPI PI Sheet" (PDF). Marine Corps Systems Command. United States Marine Corps. December 2014. Retrieved 2016-05-17.

- ↑ Granetto, Paul (January 29, 2009). "Final Report-Testing Requirements For Body Armor" (PDF). Department of Defense Inspections. Department of Defense. Retrieved May 21, 2016.

- ↑ "Hard Body Armor Insert Plates" (PDF). BAE Systems, Archived from original on 2008-08-04. BAE Systems. Archived from the original on August 4, 2008. Retrieved 2016-05-22.

- ↑ "Up to $160M for Enhanced Interceptor Vest Protection". Defense Industry Daily. Retrieved 2016-05-23.

- ↑ Soldier, Maj. Chris Getter, PEO. "Army upgrades body armor, saves money | Article | The United States Army". www.army.mil. Retrieved 2016-05-23.

- ↑ Sweeney, Heather. "Army Plans to Field New Protective Vest, Armored Shirt in 2019". Military.com. Retrieved 2016-05-23.

External links

- Army to Field Improved Body Armor at United States Army Official Homepage