Lead-cooled fast reactor

Molten lead or lead-bismuth eutectic can be used as the primary coolant in a nuclear reactor, because lead and bismuth have low neutron absorption and relatively low melting points. Neutrons are slowed less by interaction with these heavy nuclei, (thus not being neutron moderators) and therefore help make this type of reactor a fast-neutron reactor. The coolant does however serve as a neutron reflector, returning some escaping neutrons to the core.

The concept is generally very similar to sodium-cooled fast reactor, and most liquid-metal reactors have used sodium instead of lead. Few lead-cooled reactors have been constructed, including some Soviet nuclear submarine reactors in the 1970s, but a number of proposed new nuclear reactor designs are lead-cooled. Some designs are claimed to be able to circulate the primary coolant via convection without requiring pumps, at least in emergency shutdown conditions.

Generation IV reactor design

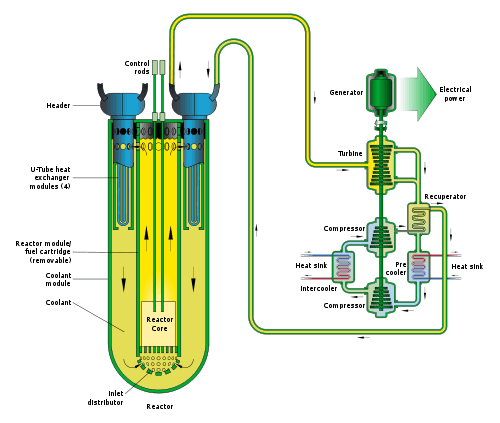

The Gen IV lead-cooled fast reactor is a nuclear reactor that features a fast neutron spectrum, molten lead or lead-bismuth eutectic coolant. Options include a range of plant ratings, including a number of 50 to 150 MWe (megawatts electric) units featuring long-life, pre-manufactured cores. Plans include modular arrangements rated at 300 to 400 MWe, and a large monolithic plant rated at 1,200 MWe. The fuel is metal or nitride-based containing fertile uranium and transuranics. A smaller capacity LFR such as SSTAR can be cooled by natural convection, larger proposals such as ELSY use forced circulation in normal power operation, but with natural circulation emergency cooling. The reactor outlet coolant temperature is typically in the range of 500 to 600 °C, possibly ranging over 800 °C with advanced materials for later designs. Temperatures higher than 800 °C are high enough to support thermochemical production of hydrogen.

Modular nuclear reactors

The LFR battery is a small turnkey-type power plant using cassette cores running on a closed fuel cycle with 15 to 20 years' refuelling interval, or entirely replaceable reactor modules. It is designed for generation of electricity on small grids (and other resources, including hydrogen and potable water).

Advantages

- Instead of refueling, the whole core can be replaced after many years of operation. Such a reactor is suitable for countries that do not plan to build their own nuclear infrastructure.

- As no electricity is required for the cooling after shutdown, this design has the potential to be safer than a water-cooled reactor.

- Liquid lead-bismuth systems can't cause an explosion and quickly solidify in case of a leak, further improving safety.

- Lead is very dense, and therefore a good shield against gamma rays.

- Lead's nuclear properties allow it to prevent a positive void coefficient, which is difficult to prevent in large sodium fast reactor cores.

- The operating pressure is very low and lead has an extremely high boiling point of 1750 degrees Celsius, which is over 1100 degrees Celsius higher than the peak coolant operating temperature. This makes significant reactor pressurization by overheating virtually impossible.

- Lead does not react significantly with water or air, unlike sodium which burns readily in air and can explode in contact with water. This allows easier, cheaper and safer containment and heat exchanger/steam generator design.

Disadvantages

- Lead and lead-bismuth are very dense, increasing the weight of the system therefore requiring more structural support and seismic protection which increases building cost.

- While lead is cheap and abundant, bismuth is expensive and quite rare. A lead-bismuth reactor will require hundreds to thousands of tonnes of bismuth depending on reactor size.

- Solidification of the lead-bismuth solution renders the reactor inoperable. However, lead-bismuth eutectic has a comparatively low melting temperature of 123.5 °C (254.3 °F), making desolidification a relatively easily accomplished task. Lead has a higher melting point of 327.5 °С, but is often used as a pool type reactor where the large bulk of lead does not easily freeze.

- By leaking and solidifying, the coolant may damage the equipment (see Soviet submarine K-64).

- Lead-bismuth produces a considerable amount of polonium, a highly radioactive and quite mobile element. This can complicate maintenance and pose a plant contamination problem. Lead produces orders of magnitudes less polonium, and so has an advantage over lead-bismuth in this regard.

Implementation

Belgium

The MYRRHA project (for Multi-purpose hYbrid Research Reactor for High-tech Applications) is a first-of-a-kind design of a nuclear reactor coupled to a proton accelerator (so-called Accelerator-driven system (ADS)). This will be a 'Lead-cooled fast reactor' with two possible configurations: sub-critical or critical. The project is managed by SCK•CEN, the Belgium center for nuclear energy. It will be built based on a first successful demonstrator: GUINEVERE.[1] The project entered a new phase of development in 2013 when a contract for the front-end engineering design was awarded to a consortium led by Areva.[2][3] MYRRHA enjoys international recognition and was listed in December 2010 by the European Commission[4] as one of 50 projects for maintaining European leadership in high-tech research in the next 20 years.

Russia/USSR

Two types of LFR reactor were used in Soviet Alfa class submarines of the 1970s. The OK-550 and BM-40A designs were both capable of producing 155MWt. They were significantly lighter than typical water-cooled reactors and had an advantage of being capable to quickly switch between maximum power and minimum noise operation modes.

A joint venture called AKME Engineering was announced on 25 December 2009 between Rosatom and En+ Group, to develop a commercial lead-bismuth reactor.[5] The SVBR-100 ('Svintsovo-Vismutovyi Bystryi Reaktor' - lead-bismuth fast reactor) is based on the Alfa designs and will produce 100MWe electricity from gross thermal power of 280MWt,[5] about twice that of the submarine reactors. They can also be used in groups of up to 16 if more power is required.[5] The coolant increases from 345 °C (653 °F) to 495 °C (923 °F) as it goes through the core.[5] Uranium oxide enriched to 16.5% U-235 could be used as fuel, and refuelling would be required every 7–8 years.[5] A prototype is planned for 2017.[6]

Another two lead cooled reactors are developed by Russians: BREST-300 and BREST-1200 [7] The BREST-300 design was completed in September 2014.[8]

WNA mentions Russia role on boosting other countries interest in this field:[9]

In 1998 Russia declassified a lot of research information derived from its experience with submarine reactors, and US interest in using Pb or Pb-Bi for small reactors has increased subsequently.

United States

According to Nuclear Engineering International, the initial design of the Hyperion Power Module will be of this type, using uranium nitride fuel encased in HT-9 tubes, using a quartz reflector, and lead-bismuth eutectic as coolant.[10]

The Lawrence Livermore National Laboratory developed SSTAR is a lead-cooled design.

Westinghouse proposes LFR project http://www.world-nuclear-news.org/NN-Westinghouse-proposes-LFR-project-1410154.html

Germany

The dual fluid reactor (DFR) is a German project combining the advantages of the molten salt reactor with the ones of the liquid metal cooled reactor.[11] As a breeder reactor the DFR can burn both natural uranium and thorium, as well as recycle nuclear waste. Due to the high thermal conductivity of the molten metal, the DFR is a inherently safe reactor (the decay heat can be removed passively).

See also

References

- ↑ Science Magazine, " Reactor-Accelerator Hybrid Achieves Successful Test Run"

- ↑ World Nuclear News, "Myrrha accelerates towards realisation"

- ↑ AREVA official website, "AREVA TA WINS CONTRACT FOR THE MYRRHA PROJECT"

- ↑ European commission, " Targeting nuclear waste with a proton beam"

- 1 2 3 4 5 "Initiative for small fast reactors". World Nuclear News. 2010-01-04. Retrieved 2010-02-05.

- ↑ "Heavy metal power reactor slated for 2017". World Nuclear News. 2010-03-23. Retrieved 2012-09-26.

- ↑ "Design features of BREST reactors and experimental work to advance the concept of BREST reactors" (PDF). US DoE, Small Modular Reactor Program. Retrieved 2013-05-16.

- ↑ http://www.world-nuclear-news.org/NN-Design-completed-for-prototype-fast-reactor-0209147.html

- ↑ http://www.world-nuclear.org/info/nuclear-fuel-cycle/power-reactors/nuclear-power-reactors/

- ↑ "Hyperion launches U2N3-fuelled, Pb-Bi-cooled fast reactor". Nuclear Engineering International. Global Trade Media. 2009-11-20. Retrieved 3 December 2009.

- ↑ Dual Fluid Reactor

- Advanced reactor, fuel cycle, and energy products workshop for universities

- Generation IV International Forum LFR website

External links

- Idaho National Laboratory Lead-Cooled Fast Reactor (LFR) Fact Sheet

- Heavy-Metal Aerosol Transport in a Lead-Bismuth Cooled Fast Reactor with In-Vessel Direct-Contact Steam Generation

- Comparison of sodium and lead-cooled fast reactors regarding reactor physics aspects, severe safety and economical issues

- RBEC-M Lead-Bismuth Cooled Fast Reactor Benchmarking Calculations

- New York Times

- Myrrha official website

- Isol@myrrha official website