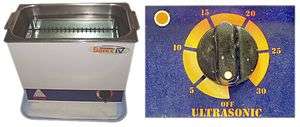

Ultrasonic cleaning

Ultrasonic cleaning is a process that uses ultrasound (usually from 20–400 kHz) and an appropriate cleaning solvent (sometimes ordinary tap water) to clean items. The ultrasound can be used with just water, but use of a solvent appropriate for the item to be cleaned and the type of soiling present enhances the effect. Cleaning normally lasts between three and six minutes, but can also exceed 20 minutes, depending on the object to be cleaned.[1]

Ultrasonic cleaners are used to clean many different types of objects, including jewellery, lenses and other optical parts, watches, dental and surgical instruments, tools, coins, fountain pens, golf clubs, fishing reels, window blinds, firearms, car fuel injectors, musical instruments, industrial parts and electronic equipment. They are used in many jewellery workshops, watchmakers' establishments, and electronic repair workshops.[2]

History

Ultrasonic cleaners began being used in industry in about 1950, and came into use as relatively inexpensive home appliances in about 1970.[3]

Process characteristics

Ultrasonic cleaning uses cavitation bubbles induced by high frequency pressure (sound) waves to agitate a liquid. The agitation produces high forces on contaminants adhering to substrates like metals, plastics, glass, rubber, and ceramics. This action also penetrates blind holes, cracks, and recesses. The intention is to thoroughly remove all traces of contamination tightly adhering or embedded onto solid surfaces. Water or solvents can be used, depending on the type of contamination and the workpiece. Contaminants can include dust, dirt, oil, pigments, rust, grease, algae, fungus, bacteria, lime scale, polishing compounds, flux agents, fingerprints, soot wax and mold release agents, biological soil like blood, and so on. Ultrasonic cleaning can be used for a wide range of workpiece shapes, sizes and materials, and may not require the part to be disassembled prior to cleaning.[4] Objects must not be allowed to rest on the bottom of the device during the cleaning process, because that will prevent cavitation from taking place on the part of the object not in contact with solvent.[5]

Design and operating principle

In an ultrasonic cleaner, the object to be cleaned is placed in a chamber containing a suitable solution (in an aqueous or organic solvent, depending on the application). In aqueous cleaners, surfactants (e.g., laundry detergent) are often added to permit dissolution of nonpolar compounds such as oils and greases. An ultrasound generating transducer built into the chamber, or lowered into the fluid, produces ultrasonic waves in the fluid by changing size in concert with an electrical signal oscillating at ultrasonic frequency. This creates compression waves in the liquid of the tank which ‘tear’ the liquid apart, leaving behind many millions of microscopic ‘voids’ or ‘partial vacuum bubbles’ (cavitation). These bubbles collapse with enormous energy; temperatures and pressures on the order of 5,000 K and 20,000 lbs per square inch are achieved;[6][7] however, they are so small that they do no more than clean and remove surface dirt and contaminants. The higher the frequency, the smaller the nodes between the cavitation points, which allows for cleaning of more intricate detail.

Transducers are usually piezoelectric (e.g. made with lead zirconate titanate (PZT), barium titanate, etc.), but are sometimes magnetostrictive. The often harsh chemicals used as cleaners in many industries are not needed, or used in much lower concentrations, with ultrasonic agitation. Ultrasonics are used for industrial cleaning, and also used in many medical and dental techniques and industrial processes.

Cleaning solution

Ultrasonic activity (cavitation) helps the solution to do its job; plain water would not normally be effective. The cleaning solution contains ingredients designed to make ultrasonic cleaning more effective. For example, reduction of surface tension increases cavitation levels, so the solution contains a good wetting agent (surfactant). Aqueous cleaning solutions contain detergents, wetting agents and other components, and have a large influence on the cleaning process. Correct composition of the solution is very dependent upon the item cleaned. Solutions are mostly used warm, at about 50–65 °C (122–149 °F), however, in medical applications it is generally accepted that cleaning should be at temperatures below 45 °C (113 °F) to prevent protein coagulation.

Water-based solutions are more limited in their ability to remove contaminants by chemical action alone than solvent solutions; e.g. for delicate parts covered with thick grease. The effort required to design an effective aqueous-cleaning system for a particular purpose is much greater than for a solvent system.

Some machines (which are not unduly large) are integrated with vapour degreasing machines using hydrocarbon cleaning fluids: Three tanks are used in a cascade. The lower tank containing dirty fluid is heated causing the fluid to evaporate. At the top of the machine there is a refrigeration coil. Fluid condenses on the coil and falls into the upper tank. The upper tank eventually overflows and clean fluid runs into the work tank where the cleaning takes place. Purchase price is higher than simpler machines, but such machines are economical in the long run. The same fluid can be reused many times, minimising wastage and pollution.

Carbon tetrachloride was used in the past, but is now prohibited as a health hazard.

Uses

Most hard, non-absorbent materials (metals, plastics, etc.) not chemically attacked by the cleaning fluid are suitable for ultrasonic cleaning. Ideal materials for ultrasonic cleaning include small electronic parts, cables, rods, wires and detailed items, as well as objects made of glass, plastic, aluminium or ceramic.[8]

Ultrasonic cleaning does not sterilize the objects being cleaned, because spores and viruses will remain on the objects after cleaning. In medical applications, sterilization normally follows ultrasonic cleaning as a separate step.[9]

Industrial ultrasonic cleaners are used in the automotive, sporting, printing, marine, medical, pharmaceutical, electroplating, disk drive components, engineering and weapons industries.

Limitations

Ultrasonic cleaning is used widely to remove flux residue from soldered circuit boards. However, some electronic components, notably MEMS devices such as gyroscopes, accelerometers and microphones can become damaged or destroyed by the high intensity vibrations they are subjected to during cleaning. Piezoelectric buzzers can work in reverse and produce voltage, which may pose a danger to their drive circuits.

See also

References

- ↑ Dietz, Ellen Roberta and Raula Badavinac (2002). Safety standards and infection control for dental hygienists. Albany, NY: Delmar Thomson Learning. p. 129. ISBN 0766826600.

- ↑ Ensminger, Dale (2009). Ultrasonics: data, equations, and their practical uses, Volume 10. Boca Raton, Florida: CRC Press (Taylor & Francis Group). p. 328. ISBN 978-0-8247-5830-1.

- ↑ Wahl, Paul (March 1970). "Put Sound Waves to Work in Your Shop". Popular Science. Retrieved 20 December 2011.

- ↑ Robert H. Todd, Dell K. Allen, and Leo Alting; Manufacturing Processes Reference Guide

- ↑ Ensminger, Dale (2009). Ultrasonics: data, equations, and their practical uses, Volume 10. Boca Raton, Florida: CRC Press (Taylor & Francis Group). pp. 328–358. ISBN 978-0-8247-5830-1.

- ↑ Henglein, A., & Gutierrez, M. (1993). Sonochemistry and sonoluminescence: Effects of external pressure. J. Phys. Chem., 1993(97), 158-162.

- ↑ Azar, Lawrence (2009, February). Cavitation in ultrasonic cleaning and cell disruption. Controlled Environments , Retrieved from "http://www.absotecthailand.com/Cavitation.pdf"

- ↑ Williams, Douglas (1994). Guide to Cleaner Technologies: Cleaning and Degreasing Process Changes. Washington DC: United States Environmental Protection Agency. p. 19.

- ↑ Simmers, Louise, and Karen Simmers-Nartker, Sharon Simmers-Kobelak (2009). Diversified Health Occupations: Seventh Edition. Clifton Park, NY: Delmar Cengage Learning Academic Resource Center. p. 381. ISBN 978-1-4180-3021-6.