Vanadium redox battery

| Specific energy | 10–20 Wh/kg (36–72 J/g) |

|---|---|

| Energy density | 15–25 Wh/L (54–65 kJ/L) |

| Charge/discharge efficiency | 75–80%<.[1][2] |

| Time durability | 20-30 years |

| Cycle durability | >100,000 cycles |

| Nominal cell voltage | 1.15–1.55 V |

The vanadium redox battery (VRB) (or Vanadium flow battery) is a type of rechargeable flow battery that employs vanadium ions in different oxidation states to store chemical potential energy.[3] The vanadium redox battery exploits the ability of vanadium to exist in solution in four different oxidation states, and uses this property to make a battery that has just one electroactive element instead of two.[4] For several reasons, including their relatively bulky size, most vanadium batteries are currently used for grid energy storage, such as being attached to power plants or electrical grids.

The first successful demonstration of the all-vanadium redox flow battery which employed vanadium in a solution of sulfuric acid in each half was by Maria Skyllas-Kazacos at the University of New South Wales in the 1980s.[5] Her design used sulfuric acid electrolytes, and was patented by the University of New South Wales in Australia in 1986.[2] The possibility of creating a vanadium flow battery was explored variously by Pissoort in 1930's,[6] NASA researchers in the 1970s, and Pellegri and Spaziante in the 1970s,[7] but none of them were successful in demonstrating the technology.

Numerous companies and organizations involved in funding and developing vanadium redox batteries including Imergy (formerly Deeya), Vionx (formerly Premium Power), UniEnergy Technologies,[8] and Ashlawn Energy[9] in the United States; Renewable Energy Dynamics Technology[10] in Ireland; Gildemeister AG (formerly Cellstrom GmbH in Austria) in Germany;[11] Cellennium in Thailand Rongke Power; Prudent Energy in China;[12] Sumitomo in Japan; H2, Inc. in South Korea;[13] and redT in Britain.[14]

The main advantages of the vanadium redox battery are:

- It can offer almost unlimited energy capacity simply by using larger electrolyte storage tanks.

- It can be left completely discharged for long periods with no ill effects.

- If the electrolytes are accidentally mixed, the battery suffers no permanent damage.

- A single state of charge between the two electrolytes avoids the capacity degradation due to a single cell in non-flow batteries.

- The electrolyte is aqueous and inherently safe and non-flammable.[15]

- The generation 3 formulation using a mixed acid solution developed by the Pacific Northwest National Laboratory operates at a high temperature allowing for passive cooling [16]

The main disadvantages with vanadium redox technology are a relatively poor energy-to-volume ratio, although the Generation 3 formulation has doubled the energy density [16] of the system complexity in comparison with standard storage batteries, and the aqueous electrolyte makes the battery heavy and therefore only useful for stationary applications.

Operation

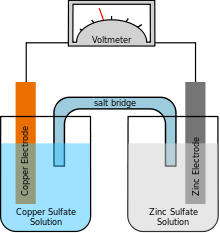

A vanadium redox battery consists of an assembly of power cells in which the two electrolytes are separated by a proton exchange membrane. Both electrolytes are vanadium-based, the electrolyte in the positive half-cells contains VO2+ and VO2+ ions, the electrolyte in the negative half-cells, V3+ and V2+ ions. The electrolytes may be prepared by any of several processes, including electrolytically dissolving vanadium pentoxide (V2O5) in sulfuric acid (H2SO4). The solution remains strongly acidic in use.

In vanadium flow batteries, both half-cells are additionally connected to storage tanks and pumps so that very large volumes of the electrolytes can be circulated through the cell. This circulation of liquid electrolytes is somewhat cumbersome and does restrict the use of vanadium flow batteries in mobile applications, effectively confining them to large fixed installations.

When the vanadium battery is charged, the VO2+ ions in the positive half-cell are converted to VO2+ ions when electrons are removed from the positive terminal of the battery. Similarly in the negative half-cell, electrons are introduced converting the V3+ ions into V2+. During discharge this process is reversed and results in a typical open-circuit voltage of 1.41 V at 25 °C.

Other useful properties of vanadium flow batteries are their very fast response to changing loads and their extremely large overload capacities. Studies by the University of New South Wales have shown that they can achieve a response time of under half a millisecond for a 100% load change, and allowed overloads of as much as 400% for 10 seconds. The response time is mostly limited by the electrical equipment. Sulfuric acid-based vanadium batteries only work between about 10 to 40 °C. Below that temperature range, the ion-infused sulfuric acid crystallizes.[17] Round trip efficiency in practical applications is around 65–75 %.[18]

Proposed improvements

Second generation vanadium redox batteries (vanadium/bromine) may approximately double the energy density and increase the temperature range in which the battery can operate.

Despite the traditional pumping requirements, nanoFlowcell AG has developed a proprietary system of energy storage for electric vehicle applications showcased through a number of Quant vehicle prototypes, using rapid replacement of electrolyte to refuel the battery.[19]

Energy density

Current production vanadium redox batteries achieve an energy density of about 25 Wh/kg (90 kJ/kg) of electrolyte. More recent research at UNSW indicates that the use of precipitation inhibitors can increase the density to about 35 Wh/kg (126 kJ/kg), with even higher densities made possible by controlling the electrolyte temperature. This energy density is quite low as compared to other rechargeable battery types (e.g., lead–acid, 30–40 Wh/kg (108–144 kJ/kg); and lithium ion, 80–200 Wh/kg (288–720 kJ/kg)).

Applications

The extremely large capacities possible from vanadium redox batteries make them well suited to use in large power storage applications such as helping to average out the production of highly variable generation sources such as wind or solar power, helping generators cope with large surges in demand or leveling out supply/demand at a transmission constrained region.

The limited self-discharge characteristics of vanadium redox batteries make them useful in applications where the batteries must be stored for long periods of time with little maintenance while maintaining a ready state. This has led to their adoption in some military electronics, such as the sensor components of the GATOR mine system. Their ability to fully cycle and stay at 0% state of charge makes them suitable for solar + storage applications where the battery must start each day empty and fill up depending upon the load and weather. Lithium Ion batteries, for example, are typically damaged when they are allowed to discharge below 20% state of charge, so they typically only operate between about 20% and 100%, meaning they are only using 80% of their nameplate capacity.[20]

Their extremely rapid response times also make them superbly well suited to UPS type applications, where they can be used to replace lead–acid batteries and even diesel generators. Also the fast response time makes them well-suited for frequency regulation. Economically neither the UPS or frequency regulation applications of the battery are currently sustainable alone, but rather the battery is able to layer these applications with other uses to capitalize on various sources of revenue. Also, these capabilities make Vanadium redox batteries an effective "all-in-one" solution for microgrids that depend on reliable operations, frequency regulation and have a need for load shifting (from either high renewable penetration, a highly variable load or desire to optimize generator efficiency through time-shifting dispatch).

Installations

There are several notable currently installed vanadium batteries:

- A 1 MW, 4 MW·h (14 GJ) UniEnergy Technologies Energy Storage system (Uni.System) owned by Avista Utilities and installed in Pullman Washington in April 2015. The system is used for load shifting, distribution deferral and frequency regulation for Avista Utilities, and for backup power for critical loads at Schweitzer Engineering Laboratories.[21]

- A 1.5 MW UPS system in a semiconductor fabrication plant in Japan.

- A 600 kW, six-hour system, installed by Prudent Energy in Oxnard, California, USA.[22]

- A 275 kW output balancer in use on a wind power project in the Tomari Wind Hills of Hokkaido.

- A 200 kW, 800 kW·h (2.9 GJ) output leveler in use at the Huxley Hill Wind Farm on King Island, Tasmania.

- A 250 kW, 2 MW·h (7.2 GJ) load leveler in use at Castle Valley, Utah.

- Two 5-kW units installed in St. Petersburg, Florida, under the auspices of USF's Power Center for Utility Explorations.

- A 100 kWh (360 MJ) unit supplied with 18 kW stacks manufactured by Cellstrom (Austria) has been installed in Vierakker (Gelderland, The Netherlands) as part of an integrated energy concept called 'FotonenBoer'/'PhotonFarmer' (InnovationNetwork/Foundation Courage).

- A 400 kW, 500 kWh (1.8 GJ) output balancer in use on a solar power project in the Bilacenge Village in Sumba Island, Indonesia.

- A 50 kW, 100 kWh (360 MJ) peak shaving for manufacturing facility in Gongju, South Korea.[23]

- A 5 kW, 60 kWh unit integrated with photovoltaic generation at University of Évora, Portugal.[24]

- A 100 kW, 1.26 MWh installation is planned for the island of Gigha, Scotland.[25]

- A 5 MW, 10 MW·h (36 GJ) system at the Woniushi wind power farm was connected to the Liaoning Power Grid, China, on 23 May 2013.[26]

- 1 MW, 5 MW·h (18 GJ) installed by Sumitomo Electric Industries in Yokohama.

- 100 kW, 600 kWh unit, installed by Prudent Energy & ABB in Kolarovo, Slovakia.

- 200 kW 800kWh unit, planned by Solibra System Montage in Koblenz, Germany.

See also

| Wikimedia Commons has media related to Vanadium redox batteries. |

- Polysulfide bromide battery

- Battery (electricity)

- Flow battery

- Lead–acid battery

- Electrochemical cell

- Fuel cell

- Energy storage

References

- ↑ Vanadium Battery Group University of New South Wales

- 1 2 M. Skyllas-Kazacos, M. Rychcik and R. Robins, in AU Patent 575247 (1986), to Unisearch Ltd.

- ↑ Laurence Knight (14 Jun 2014). "Vanadium: The metal that may soon be powering your neighbourhood". BBC. Retrieved 2 Mar 2015.

- ↑ Alotto, P.; Guarnieri, M.; Moro, F. (2014). "Redox Flow Batteries for the storage of renewable energy: a review". Renewable & Sustainable Energy Reviews. 29: 325–335. doi:10.1016/j.rser.2013.08.001.

- ↑ M. Rychcik and M. Skyllas-Kazacos, J. Power Sources, 22 (1988) 59–67

- ↑ P. A. Pissoort, in FR Patent 754065 (1933)

- ↑ A. Pelligri and P. M. Spaziante, in GB Patent 2030349 (1978), to Oronzio de Nori Impianti Elettrochimici S.p.A.

- ↑ Steve Wilhelm (3 Jul 2014). "Liquid battery the size of a truck, will give utilities a charge". Puget Sound Business Journal. Retrieved 2 May 2015.

- ↑ BILL HAGSTRAND (23 Aug 2013). "Vanadium redox: powering up local communities". Crain's Cleavland Business. Retrieved 2 May 2015.

- ↑ "US clean-tech investments leap to US$1.1bn. Where's Ireland at?". Silicon Republic. 11 Apr 2011. Retrieved 2 May 2015.

- ↑ "a+f acquires majority stake in Cellstrom". DMG Mori Seiki AG. 16 April 2010. Retrieved 21 June 2014.

- ↑ Jeff St. John (2 Mar 2010). "Made in China: Prudent Energy Lands $22M For Flow Batteries". GigaOm. Retrieved 2 May 2015.

- ↑ (주)에이치투

- ↑ redT energy storage - Maximise Your Energy

- ↑ UniEnergy Technologies Products Accessed 21 Jan 2016.

- 1 2 Miller, Kelsey. UniEnergy Technologies Goes from Molecules to Megawatts, Clean Tech Alliance, 7 July 2014. Accessed 21 Jan 2016.

- ↑ DOE/Pacific Northwest National Laboratory (17 Mar 2011). "Electric Grid Reliability: Increasing Energy Storage in Vanadium Redox Batteries by 70 Percent". Science Daily. Retrieved 2 Mar 2015.

- ↑ VRB Power Systems FAQ Archived 13 February 2010 at the Wayback Machine.

- ↑ "Electric Vehicle Refuelling System (EVRS) used in conjunction with Vanadium Redox Flow Technology". REDT Energy Storage.

- ↑ Allbright, Greg, et. al. A Comparison of Lead Acid to Lithium-ion in Stationary Storage Applications All Cell, March 2012

- ↑ Wesoff, Eric, St. John, Jeff. Largest Capacity Flow Battery in North America and EU is Online, Greentech Media, June 2015. Accessed 21 Jan 2016.

- ↑ "Peak Shaving and Demand Charge Avoidance: Prudent Energy Vanadium Redox Battery Energy Storage System (VRB-ESS®)". Energy Storage Association, ESA. Retrieved 20 July 2014.

- ↑ "Samyoung Vanadium Redox Flow Battery Project". H2, Inc.

- ↑ "Successful Installation of Vanadium Storage System in Collaboration with FP7 and the European Commission". REDT Energy Storage.

- ↑ "£3.6m from DECC to Develop 1.26MWh Utility Scale Vanadium Redox Flow Battery". REDT Energy Storage.

- ↑

Additional references

- Presentation paper from the IEEE summer 2001 conference

- UNSW Site on Vanadium batteries

- Report by World Energy

- World Map Of Global Vanadium Deposits Vanadium geology is fairly unusual compared to a base metals ore body.

- "Improved Redox Flow Batteries For Electric Cars". ScienceDaily/Fraunhofer-Gesellschaft. 13 October 2009. Retrieved 21 June 2014.

External links

- VRB at UNSW

- VRB at everything2

- The Need for Vanadium Redox Energy Storage in Wind Turbine Generators Net electricity generation from all forms of renewable energies in America increased by over 15% between 2005 and 2009.