Weld nut

A weld nut is a special type of nut specifically designed to be welded to another object. There are various types for different applications.

Types

- Round base nuts

These nuts have a long threaded cylinder with a large circular base to make welding easy. They also sometimes have projections (known as weld nibs or bosses) to keep the nut from warping while welding with a high current.[1]

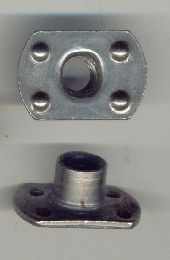

- Slab base nuts

These are very similar to the round base nuts, but with an obround, or slab shaped, base. These are used in channels, tubes, or other tight quarters.[1]

- Tab base nuts

Tab base nuts are designed for spot welding on flat workpieces. They have a locating boss around the threads to locate it in a pilot hole.[1]

- Hex & square nuts

These nuts are very similar to standard square or hex nuts, but have a locating boss and welding projections. The bosses also keep weld spatter out of the threads.[2]

- Retainer weld nuts

Retainer weld nuts, also known as bridge weld nuts, have a floating nut retained inside a retainer to compensate for inconsistencies. The retainer is welded to the workpiece while the nut is allowed to float.[2]

- Tube end nuts

Tube end nuts are sized to fit into the end of standard sized tubing, thus creating a threaded tube from standard stock.[2]

References

Notes

Bibliography

- McMaster-Carr catalog (114th ed.), McMaster-Carr.