Dimethyl terephthalate

| |

| Names | |

|---|---|

| Preferred IUPAC name

Dimethyl benzene-1,4-dicarboxylate | |

| Other names

Dimethyl terephthalate 1,4-Benzenedicarboxylic acid dimethyl ester Dimethyl 4-phthalate Dimethyl p-phthalate Di-Me terephthalate Methyl 4-carbomethoxybenzoate Methyl-p-(methoxycarbonyl)benzoate Methyl terephthalate Terephthalic acid methyl ester | |

| Identifiers | |

| 120-61-6 | |

| 3D model (Jmol) | Interactive image Interactive image |

| Abbreviations | DMT |

| 1107185 | |

| ChemSpider | 13863300 |

| ECHA InfoCard | 100.004.011 |

| EC Number | 204-411-8 |

| MeSH | Dimethyl+4-phthalate |

| PubChem | 8441 12241382 (2H4) |

| RTECS number | WZ1225000 |

| |

| |

| Properties | |

| C10H10O4 | |

| Molar mass | 194.19 g·mol−1 |

| Appearance | white solid |

| Density | 1.2 g/cm3, ? |

| Melting point | 142 °C (288 °F; 415 K) |

| Boiling point | 288 °C (550 °F; 561 K) |

| Acidity (pKa) | -7.21 |

| Basicity (pKb) | -6.60 |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| | |

| Infobox references | |

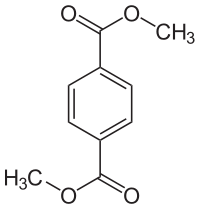

Dimethyl terephthalate (DMT) is an organic compound with the formula C6H4(CO2CH3)2. It is the diester formed from terephthalic acid and methanol. It is a white solid that melts to give a distillable colourless liquid.[1]

Production

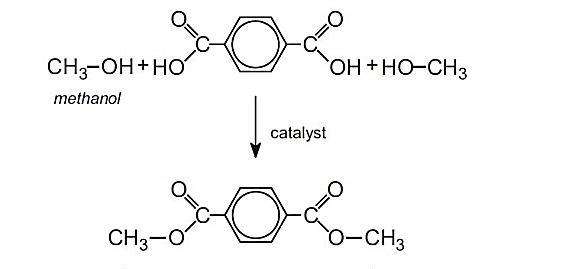

Dimethyl terephthalate (DMT) has been produced in a number of ways. Conventionally and still of commercial value is the direct esterification of terephthalic acid. Alternatively, it can be prepared by alternating oxidation and methyl-esterification steps from p-xylene via methylp-toluate.[1]

Dimethyl Terephthalate (DMT) (Witten Process)

The common method for the production of DMT from para-xylene (PX) and methanol consists of four major steps: oxidation, esterification, distillation, and crystallization. A mixture of p-xylene (PX) and p-Toluic ester (PT) is oxidized with air in the presence of a heavy metal catalyst (Co/Mn). The acid mixture resulting from the oxidation is esterified with methanol (MeOH, CH3OH) to produce a mixture of esters. The crude ester mixture is distilled to remove all the heavy boilers and residue produced; the lighter esters are recycled to the oxidation section. The raw DMT is then sent to the crystallization section to remove DMT isomers, residual acids and aromatic aldehydes.[2]

2) Esterification of the resulting acid with methanol results in Methyl p-toluate at 250⁰C and 2500 kPa and subsequent oxidation and esterification of Methyl p-toluate yields Dimethyl terephthalate (DMT) as shown in the below reaction:[1]

Dimethyl Terephthalate (DMT) production through Direct Esterification

If highly impure Terephthalic acid is available, DMT can be made in a separate process by esterification with methanol to dimethyl terephthalate which is then purified by distillation:

- C8H6O4 (TPA) + 2CH3OH (Methanol) → C10H10O4 (DMT) + 2 H2O

at presence of o-xylene at 250–300 ⁰C.

Use

DMT is used in the production of polyesters, including polyethylene terephthalate (PET), polytrimethylene terephthalate (PTT), and polybutylene terephthalate (PBT). It consists of benzene substituted with carboxymethyl groups (CO2CH3) at the 1 and 4 positions. Because DMT is volatile, it is an intermediate in some schemes for the recycling of PET, e.g. from plastic bottles.

Hydrogenation of DMT affords the diol cyclohexanedimethanol, which is a useful monomer.

References

- 1 2 3 Richard J. Sheehan "Terephthalic Acid, Dimethyl Terephthalate, and Isophthalic Acid" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, 2005.doi:10.1002/14356007.a26_193

- ↑ http://www.gtctech.com/technology-licensing/polyester-technologies/dimethyl-terephthalate-technology/

External links

- Supplier:Teijin Limited http://www.teijin.com/products/chemicals/dmt/

- http://www.inchem.org/documents/icsc/icsc/eics0262.htm

- International Chemical Safety Card 0262

- U.S. National Library of Medicine: Hazardous Substances Databank – Dimethyl+terephthalate