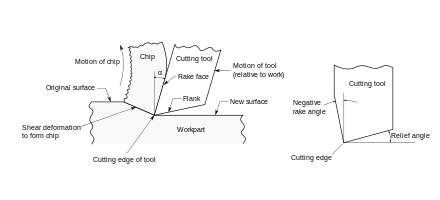

Rake angle

Rake angle is a parameter used in various cutting and machining processes, describing the angle of the cutting face relative to the work. There are two rake angles, namely the back rake angle and side rake angle, both of which help to guide chip flow. There are three types of rake angles: positive, negative, and zero.

Generally, positive rake angles:

- Make the tool more sharp and pointed. This reduces the strength of the tool, as the small included angle in the tip may cause it to chip away.

- Reduce cutting forces and power requirements.

- Helps in the formation of continuous chips in ductile materials.

- Can help avoid the formation of a built-up edge.

Negative rake angles, by contrast:

- Make the tool more blunt, increasing the strength of the cutting edge.

- Increase the cutting forces.

- Can increase friction, resulting in higher temperatures.

- Can improve surface finish.

A zero rake angle is the easiest to manufacture, but has a larger crater wear when compared to positive rake angle as the chip slides over the rake face.[1]

Recommended rake angles can vary depending on the material being cut, tool material, depth of cut, cutting speed, machine, and setup. This table summarizes recommended rake angles for single-point turning on a lathe; rake angles for drilling, milling, or sawing are often different.

| Material being cut | Rake [2] | Rake [3] | Rake [4] |

|---|---|---|---|

| Aluminum | 12°-25° | 40° | 35° |

| Brass | 3°-14° | 8° | 0° |

| Bronze | 5°-14° | 0° | |

| Cast Iron, Gray | 0°-6° | 0° | 5° |

| Copper | 18°-25° | 16° | |

| PVC | 20°-25° | ||

| Stainless Steel | 8°-10° | 8° | 8° |

| Steel, Mild | 12°-14° | 20° | 8°-15° |

| Titanium | 0°-4° |