Tin dioxide

| |

| |

| Names | |

|---|---|

| IUPAC name

Tin (IV) Oxide | |

| Other names

Stannic oxide, Tin(IV) oxide, Flowers of tin,[1] Cassiterite | |

| Identifiers | |

| 18282-10-5 13472-47-4 (hydrate) | |

| 3D model (Jmol) | (O=Sn=O): Interactive image |

| ChemSpider | 26988 |

| ECHA InfoCard | 100.038.311 |

| EC Number | 242-159-0 |

| PubChem | 29011 |

| RTECS number | XQ4000000 |

| |

| |

| Properties | |

| O2Sn | |

| Molar mass | 150.71 g·mol−1 |

| Appearance | White or light grey powder[2] |

| Odor | Odorless |

| Density | 6.95 g/cm3 (20 °C)[3] 6.85 g/cm3 (24 °C)[4] |

| Melting point | 1,630 °C (2,970 °F; 1,900 K)[3][4] |

| Boiling point | 1,800–1,900 °C (3,270–3,450 °F; 2,070–2,170 K) Sublimes[3] |

| Insoluble[4] | |

| Solubility | Soluble in hot concentrated alkalis,[4] concentrated acids Insoluble in alcohol[3] |

| −4.1·10−5 cm3/mol[4] | |

| Refractive index (nD) |

2.006[5] |

| Structure | |

| Rutile tetragonal, tP6[6] | |

| P42/mnm, No. 136[6] | |

| 4/m 2/m 2/m[6] | |

| α = 90°, β = 90°, γ = 90° | |

| Octahedral (Sn4+) Trigonal planar (O2−) | |

| Thermochemistry | |

| 52.6 J/mol·K[4] | |

| Std molar entropy (S |

49.04 J/mol·K[4][7] |

| Std enthalpy of formation (ΔfH |

−577.63 kJ/mol[4][7] |

| Gibbs free energy (ΔfG˚) |

−515.8 kJ/mol[4] |

| Hazards | |

| Safety data sheet | ICSC 0954 |

| NFPA 704 | |

| Lethal dose or concentration (LD, LC): | |

| LD50 (median dose) |

> 20 g/kg (rats, oral)[8] |

| US health exposure limits (NIOSH): | |

| PEL (Permissible) |

none[2] |

| REL (Recommended) |

TWA 2 mg/m3[2] |

| IDLH (Immediate danger) |

N.D.[2] |

| Related compounds | |

| Tin(II) oxide | |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| | |

| Infobox references | |

Tin (IV) oxide, also known by the systematic name stannic oxide in the older notation, is the inorganic compound with the formula SnO2. It is not named tin dioxide because Tin is a Type II Metal, and so is named Tin (IV) Oxide by nomenclature. The mineral form of SnO2 is called cassiterite, and this is the main ore of tin.[9] With many other names (see infobox), this oxide of tin is the most important raw material in tin chemistry. This colourless, diamagnetic solid is amphoteric.

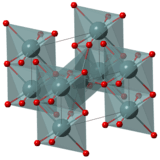

Structure

It crystallises with the rutile structure, wherein the tin atoms are six coordinate and the oxygen atoms three coordinate.[9] SnO2 is usually regarded as an oxygen-deficient n-type semiconductor.[10] Hydrous forms of SnO2 have been described in the past as stannic acids, although such materials appear to be hydrated particles of SnO2 where the composition reflects the particle size.[11]

Preparation

Tin (IV) Oxide occurs naturally but is purified by reduction to the metal followed by burning tin in air.[11] Annual production is in the range of 10 kilotons.[11] SnO2 is reduced industrially to the metal with carbon in a reverberatory furnace at 1200-1300 °C.[12]

Amphoterism

Although SnO2 is insoluble in water, it is an amphoteric oxide, although cassiterite ore has been described as difficult to dissolve in acids and alkalis.[13] "Stannic acid" refers to hydrated tin (IV) oxide, SnO2, which is also called "stannic hydroxide."

Tin oxides dissolve in acids. Halogen acids attack SnO2 to give hexahalostannates,[14] such as [SnI6]2−. One report describes reacting a sample in refluxing HI for many hours.[15]

- SnO2 + 6 HI → H2SnI6 + 2 H2O

Similarly, SnO2 dissolves in sulfuric acid to give the sulfate:[11]

- SnO2 + 2 H2SO4 → Sn(SO4)2 + 2 H2O

SnO2 dissolves in strong base to give "stannates," with the nominal formula Na2SnO3.[11] Dissolving the solidified SnO2/NaOH melt in water gives Na2[Sn(OH)6]2, "preparing salt," which is used in the dye industry.[11]

Uses

In conjunction with vanadium oxide, it is used as a catalyst for the oxidation of aromatic compounds in the synthesis of carboxylic acids and acid anhydrides.[9]

Ceramic glazes

Tin (IV) oxide has long been used as an opacifier and as a white colorant in ceramic glazes.[16] This has probably led to the discovery of the pigment lead-tin-yellow, which was produced using tin (IV) oxide as a compound.[17] The use of tin (IV) oxide has been particularly common in glazes for earthenware, sanitaryware and wall tiles; see the articles tin-glazing and Tin-glazed pottery. Tin oxide remains in suspension in vitreous matrix of the fired glazes, and, with its high refractive index being sufficiently different from the matrix, light is scattered, and hence increases the opacity of the glaze. The degree of dissolution increases with the firing temperature, and hence the extent of opacity diminishes.[18] Although dependent on the other constituents the solubility of tin oxide in glaze melts is generally low. Its solubility is increased by Na2O, K2O and B2O3, and reduced by CaO, BaO, ZnO, Al2O3, and to a limited extent PbO.[19]

SnO2 has been used as pigment in the manufacture of glasses, enamels and ceramic glazes. Pure SnO2 gives a milky white colour; other colours are achieved when mixed with other metallic oxides e.g. V2O5 yellow; Cr2O3 pink; and Sb2O5 grey blue.[11]

Polishing

Tin (IV) oxide can be used as a polishing powder,[11] sometimes in mixtures also with lead oxide, for polishing glass, jewelery, marble and silver.[1] Tin (IV) oxide for this use is sometimes called as "putty powder"[13] or "jeweler's putty".[1]

Glass coatings

SnO2 coatings can be applied using chemical vapor deposition, vapour deposition techniques that employ SnCl4[9] or organotin trihalides[20] e.g. butyltin trichloride as the volatile agent. This technique is used to coat glass bottles with a thin (<0.1 μm) layer of SnO2, which helps to adhere a subsequent, protective polymer coating such as polyethylene to the glass.[9]

Thicker layers doped with Sb or F ions are electrically conducting and used in electroluminescent devices.[9]

Gas sensing

SnO2 wires are commonly used as the detecting element in carbon monoxide detectors.

SnO2 is used in sensors of combustible gases. In these the sensor area is heated to a constant temperature (few hundred °C) and in the presence of a combustible gas the electrical resistivity drops.[21] Doping with various compounds has been investigated (e.g. with CuO[22]). Doping with cobalt and manganese, gives a material that can be used in e.g. high voltage varistors.[23] Tin (IV) oxide can be doped with the oxides of iron or manganese.[24]

References

- 1 2 3 "Material Name: stannic oxide". Museum of Fine Arts, Boston. 2007-02-10. Retrieved 2013-03-29.

- 1 2 3 4 "NIOSH Pocket Guide to Chemical Hazards #0616". National Institute for Occupational Safety and Health (NIOSH).

- 1 2 3 4 CID 29011 from PubChem

- 1 2 3 4 5 6 7 8 9 Lide, David R., ed. (2009). CRC Handbook of Chemistry and Physics (90th ed.). Boca Raton, Florida: CRC Press. ISBN 978-1-4200-9084-0.

- ↑ Pradyot, Patnaik (2003). Handbook of Inorganic Chemicals. The McGraw-Hill Companies, Inc. p. 940. ISBN 0-07-049439-8.

- 1 2 3 4 Baur, W.H. (1956). "Über die Verfeinerung der Kristallstrukturbestimmung einiger Vertreter des Rutiltyps: TiO2, SnO2, GeO2 und MgF2". Acta Crystallographica. 9 (6): 515–520. doi:10.1107/S0365110X56001388.

- 1 2 Stannic oxide in Linstrom, P.J.; Mallard, W.G. (eds.) NIST Chemistry WebBook, NIST Standard Reference Database Number 69. National Institute of Standards and Technology, Gaithersburg MD. http://webbook.nist.gov (retrieved 2014-07-04)

- 1 2 "MSDS of Tin(IV) oxide". https://www.fishersci.ca. Fisher Scientific. Retrieved 2014-07-04. External link in

|website=(help) - 1 2 3 4 5 6 Greenwood, Norman N.; Earnshaw, Alan (1984). Chemistry of the Elements. Oxford: Pergamon Press. pp. 447–48. ISBN 0-08-022057-6.

- ↑ Solid State Chemistry: An Introduction Lesley Smart, Elaine A. Moore (2005) CRC Press ISBN 0-7487-7516-1

- 1 2 3 4 5 6 7 8 Holleman, A. F.; Wiberg, E. (2001), Inorganic Chemistry, San Diego: Academic Press, ISBN 0-12-352651-5

- ↑ Tin: Inorganic chemistry,J L Wardell, Encyclopedia of Inorganic Chemistry ed R. Bruce King, John Wiley & Son Ltd., (1995) ISBN 0-471-93620-0

- 1 2 Inorganic & Theoretical chemistry, F. Sherwood Taylor, Heineman, 6th Edition (1942)

- ↑ Donaldson & Grimes in Chemistry of tin ed. P.G. Harrison Blackie (1989)

- ↑ Earle R. Caley (1932). "The Action Of Hydriodic Acid On Stannic Oxide". J. Am. Chem. Soc. 54 (8): 3240–3243. doi:10.1021/ja01347a028.

- ↑ ’The Glazer’s Book’ – 2nd edition. A.B.Searle.The Technical Press Limited. London. 1935.

- ↑ Hermann Kühn, 1967, "Blei-Zinn-Gelb und seine Verwendung in der Malerei", Farbe und Lack 73: 938-949

- ↑ ’A Treatise On Ceramic Industries.’ E.Bourry. Fourth edition. Scott, Greenwood & son. London. 1926.

- ↑ ’Ceramic Glazes’ Third edition. C.W.Parmelee & C.G.Harman. Cahners Books, Boston, Massachusetts. 1973.

- ↑ US 4130673

- ↑ Joseph Watson The stannic oxide semiconductor gas sensor in The Electrical engineering Handbook 3d Edition; Sensors Nanoscience Biomedical Engineering and Instruments ed R.C Dorf CRC Press Taylor and Francis ISBN 0-8493-7346-8

- ↑ Wang, Chun-Ming; Wang, Jin-Feng; Su, Wen-Bin (2006). "Microstructural Morphology and Electrical Properties of Copper- and Niobium-Doped Tin (IV) oxide Polycrystalline Varistors". Journal of the American Ceramic Society. 89 (8): 2502–2508. doi:10.1111/j.1551-2916.2006.01076.x.

- ↑ Dibb A.; Cilense M; Bueno P.R; Maniette Y.; Varela J.A.; Longo E. (2006). "Evaluation of Rare Earth Oxides doping SnO2.(Co0.25,Mn0.75)O-based Varistor System". Materials Research. 9 (3): 339–343. doi:10.1590/S1516-14392006000300015.

- ↑ A. Punnoose; J. Hays; A. Thurber; M. H. Engelhard; R. K. Kukkadapu; C. Wang; V. Shutthanandan & S. Thevuthasan (2005). "Development of high-temperature ferromagnetism in SnO2 and paramagnetism in SnO by Fe doping". Phys. Rev. B. 72 (8): 054402. doi:10.1103/PhysRevB.72.054402.

Further reading

- "How Pilkington Energy Advantage™ Low-E Glass Works" (PDF). Pilkington Group Limited. 18 July 2005. Retrieved 2012-12-02. Technical discussion of how SnO2:F is used in low-emissivity (low-E) windows. The report includes reflectance and transmittance spectra.

- "NIOSH Pocket Guide to Chemical Hazards - Tin(IV) oxide (as Sn)". Centers for Disease Control and Prevention. 4 April 2011. Retrieved 2013-11-05. Information on chemical safety and exposure limits