Carnegie Steel Company

|

Blast furnaces and iron ore at the Carnegie-Illinois Steel Corporation mills | |

| Industry | Steel |

|---|---|

| Successor | U.S. Steel |

| Founded | 1892 |

| Headquarters | Pittsburgh, Pennsylvania |

Key people |

Andrew Carnegie Henry Clay Frick |

Carnegie Steel Company was a steel producing company primarily created by Andrew Carnegie and several close associates, in order to manage businesses at steel mills in the Pittsburgh, Pennsylvania area in the late 19th century. The company formed in 1892 and was subsequently sold in 1901 in one of the largest ever business transactions of the early 20th century, to become the major component of the United States Steel Corporation. The subsequent sale made Carnegie one of the richest men in history.

Creation

Carnegie began the construction of his first steel mill, the Edgar Thomson Steel Works in 1872 at Braddock, Pennsylvania.[1] The Thomson Steel Works began producing rails in 1874.[2] Owing to a combination of low wages, efficient technology infrastructure investment and an efficient organisation, the mill was able to produce cheap steel, which sold for a large profit in the growing markets of industrial development. Carnegie alone estimated that 40% was returned on the investment i.e. a profit of $40,000 from a $100,000 investment in the mill.[3]

The profits made by the Edgar Thomson Steel Works were sufficiently great to permit Carnegie and a number of his associates, including Henry Clay Frick to purchase other nearby steel mills. These included the Homestead Steel Works which Carnegie acquired in 1883.[4] The presence of the Allegheny, Monongahela, and Ohio rivers provided a way to transport the heavy materials associated with the steel-making industry. Each plant was located close to or alongside a river.

Carnegie agreed to Frick's subsequent proposal that the various plants and assets be consolidated into one company. This consolidation occurred on July 1, 1892 with the formation of the Carnegie Steel Company.[5]

Operations

The company headquarters were located in the Carnegie Building, an early skyscraper in Downtown Pittsburgh.[6] Built to show its use of steel in its construction, the building was fifteen stories high, and was left uncovered for a full year. The Carnegie Building was demolished in 1952. It was later rebuilt as a memorial in 2012.

Carnegie made major technological innovations in the 1880s, especially the installation of the open hearth furnace system at Homestead in 1886. It now became possible to make steel suitable for structural beams and for armor plate for the US Navy, which paid far higher prices for the premium product. In addition the plant moved increasingly toward the continuous system of production. Carnegie installed vastly improved systems of material-handling, like overhead cranes, hoists, charging machines, and buggies. All of this greatly sped the process of steelmaking, and allowed the production of far vaster quantities of steel. As the mills expanded the labor force grew rapidly, especially less skilled workers. The more skilled union members reacted with the unsuccessful 1892 Homestead Strike, along with demands for reduced working hours and against pay cuts. After the unsuccessful strike the company continued to expand and profits grew year on year, with the company having earned net profits of $21 million in 1899.[7]

J&L Steel was the most important competitor to the Carnegie Steel Company and U. S. Steel in the vicinity of Pittsburgh.

Sale

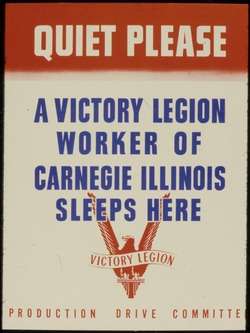

Carnegie Steel Company was sold in 1901 to the United States Steel Corporation; a newly formed organisation, set up by Pierpont Morgan.[8] It sold for $400 million ($13.3 billion today), of which $226 million went to Carnegie himself.[9] U. S. Steel was a conglomerate with subsidiary companies. The name of the subsidiary company was changed to the Carnegie-Illinois Steel Company in 1936.

20th-century steel production

Changes in the way in which steel is produced had already appeared before the Carnegie Steel Company was sold. Steel manufacturers had begun to abandon the Bessemer converters and install open-hearth furnaces. Open-hearth furnaces were widely employed until the 1980s when the basic oxygen steelmaking, electric arc furnace and continuous casting made them obsolete. Currently, employment is extraordinarily low at the remaining plants which have been a part of the Carnegie Steel Company since 1900, though in Braddock the Edgar Thomson Steel Works is still active, producing steel slabs that are shipped up river to the Irvin Works in West Mifflin to be finished coils.

See also

References

Further reading

- Krass, Peter (2002). Carnegie. p. 612. A standard scholarly biography, along with Nasaw and Wall.

- Krause, Paul (1992). The Battle for Homestead, 1880–1892: Politics, Culture, and Steel. University of Pittsburgh Press. p. 548.

- Nasaw, David (2006). Andrew Carnegie. Major biography along with Krass and Wall.

- Misa, Thomas J. (1995). A Nation of Steel: The Making of Modern America, 1865–1925.

- Sabadasz, Joel (1992). "The Development of Modern Blast Furnace Practice: The Monongahela Valley Furnaces of the Carnegie Steel Company, 1872–1913". IA, The Journal of the Society for Industrial Archeology. 18 (1/2). JSTOR 40968252.

- Wall, Joseph (1970). Andrew Carnegie. Oxford University Press. p. 1137. A standard biography along with Nasaw and Krass.