Ventile

Ventile, a registered trademark, is a high-quality woven cotton fabric first developed by scientists at the Shirley Institute in Manchester, England, originally to replace a shortage of flax that was used for fire hoses and water buckets. Its properties also found use in pilots' immersion suits.[1]

The current manufacturers of Ventile are Stotz, a Swiss company which sells the fabric under the name EtaProof[2] and Talbot Weaving Ltd. in Chorley, Lancashire which also weaves ventile fabric.[3]

Technical detail

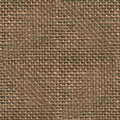

It is densely woven from 100% cotton using a long staple fibre. Although weatherproof, it is not coated or laminated; the combination of a dense weave and the swelling of the fibres when wet provide excellent weatherproofing.[1] The natural product offers a high level of comfort, look and feel and is waterproof and windproof, but breathable, durable and quiet in use. It also has good resistance to tearing and burning.[1][4] It is not as light in weight as synthetic fabrics, particularly when wet.[4]

| L34/5640 | L24/5620 | L24RS/5620RS | L19/5610 | L27/5635 | L28/5630 | Dry520 | |

|---|---|---|---|---|---|---|---|

| Fabric weight(g/m2) | 170 | 200 | 210 | 240 | 270 | 290 | 520 |

| Threads/cm warp | 95 | 81 | 68 | 71 | 16.5 | ||

| Threads/cm weft | 35 | 30 | 26 | 11.5 | |||

| Breaking strength warp minimum(N/5 cm) | 1000 | 1100 | 1200 | 1400 | 1200 | 1500 | 2500 |

| Breaking strength weft minimum(N/5 cm) | 650 | 750 | 1000 | 1400 | 2200 | ||

| Tear strength warp minimum(g) | 900 | 1200 | 1300 | 1800 | 2200 | 2000 | |

| Tear strength weft minimum(g) | 650 | 750 | 850 | 1600 | 1500 | 1600 | 1500 |

| Impregnation of DWR | fluorocarbon | ||||||

| Water absorption(max. %) | 10 | ||||||

| Resistance to water hydrostatic head(mm) | 750 | 750 | 600 | 750 | 900 | 400-500 | |

| Oil repellency(rating) | 5-6 | 5 | 5-6 | ||||

| Ventile-2015 prices(£/m2)[7] | 22.00 | 19.60 | 22.50 | 21.70 | 30.00 | 29.70 | 20.20 |

| EtaProof-2015 prices(€/m2)[8] | 25.00 | 22.00 | 25.00 | 25.00 | 25.00 | 25.00 | 22.00 |

L24/5620 and L19/5610 are made also in Organic[9] way, denominated 5620.1 RUC and 5610.1 RUC respectively, replacing the fluorocarbon of DWR with paraffin wax. With this change, three properties worsened:[6] Water absorption changed from 10% to 15%, Resistance to water hydrostatic head changed from 750mm to 600mm and Oil repellency changed from 5-6 to 0.

Uses

Fabrics made from the material are used in outerwear performance garments and have military, medical and workwear applications.

Ventile is still used in military uniforms, especially for pilots flying over water.[10] It is not often used in the United States, but in Europe, especially in the UK, it has had a revival with the bushcraft movement. It is popular with birdwatchers and naturalists because, unlike synthetic fabrics such as Gore-Tex, it is quiet in use.[4] It is used by survivalists and bushcrafters in the European forests because of its good resistance to tearing and burning. It is also widely used in polar expeditions. Lighter-weight artificial fibers are the preference among mountaineers.

Among companies producing Ventile clothing are the Scottish clothing company HillTrek,[11] Snowsled of Gloucestershire[12] and Snugpak of West Yorkshire in England,[13] and Wiggy's of Grand Junction, Colorado, USA.[1][14] The Private White V.C.[15] luxury British clothing brand based in Manchester, UK creates garments with a distinct military influence and uses Ventile cloth for many of their waterproof jackets. The brand have also pioneered 'seam sealing' in Ventile clothing - the internal taping of a jacket's seams to further protect the wearer from wind and rain.

References

- 1 2 3 4 Ventile Fabrics - Talbot Weaving (Chorley) Ltd

- ↑ EtaProof Web site

- ↑ wro Ventile History

- 1 2 3 Review of a jacket made of Ventile

- ↑ "Ventile® Specifications". Ventile Fabrics. Retrieved June 26, 2016.

- 1 2 "Technical Data". Stotz, Architechts of Fabrics. Retrieved June 26, 2016.

- ↑ "Ventile Fabrics Trade Price List" (PDF). Feralculture community. Retrieved June 26, 2016.

- ↑ "Eta®Proof Price List 2015". Retrieved June 26, 2016.

- ↑ "EtaProof Organic Cotton". Stotz, Architechts of Fabrics. Retrieved June 26, 2016.

- ↑ Ventile Fabrics: Uses

- ↑ HillTrek Web site

- ↑ Snowsled Web site

- ↑ Snugpak Web site

- ↑ Wiggy's Web site

- ↑ Private White V.C. Web site

.svg.png)