Pencil sharpener

A pencil sharpener (also referred to in Ireland as a parer or topper)[1] is a device for sharpening a pencil's writing point by shaving away its worn surface. Pencil sharpeners may be operated manually or by an electric motor.

History

Before the development of dedicated pencil sharpeners, a pencil was sharpened by whittling it with a knife. Pencil sharpeners made this task much easier and gave a more uniform result. Some specialized types of pencils, such as carpenter's pencils are still usually sharpened with a knife, due to their flat shape, though since the 2000s[2] a fixed-blade device with a rotatable collar has become available.

French mathematician Bernard Lassimonne applied for the first patent (French patent #2444) on pencil sharpeners in 1828, but it was not until 1847 that the pencil sharpener in its recognisable modern form was invented by fellow Frenchman Thierry des Estivaux.[3] The first American pencil sharpener was patented by Walter K. Foster of Bangor, Maine in 1855.[4] Electric pencil sharpeners for offices have been made since at least 1917.[5]

They now come in a wide array of colors and shapes. It is common for traditional sharpeners to have a case around them to collect the shavings. It can be removed for emptying the shavings into a compost bin.

In May 2011, tourism officials in Logan, Ohio put on display, in its regional welcome center, hundreds of pencil sharpeners which had been collected by Rev. Paul Johnson, an Ohio minister who died in 2010. Johnson, a World War II veteran, had kept his collection of more than 3,400 sharpeners in a small shed, outside his home in Carbon Hill in southeast Ohio. He had started collecting after his wife gave him a few pencil sharpeners as a gift in the late 1980s. He kept them organized into categories, including cats, Christmas, and Disneyland. The oldest was 105 years old.[6]

Manual sharpeners

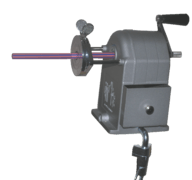

Prism sharpeners or mechanical sharpener

So-called "prism" sharpeners, also called "manual" or "pocket" sharpeners in the United States, have no moving parts and are typically the smallest and cheapest commonly used "pencil sharpener" on the market. The most simple common variety is a small and rectangular prism or block, only about 1 × 5/8 × 7/16 inch (2.5 × 1.7 × 1.1 cm) in size. The block-shaped sharpener consists of a combined point-shaping cone that is aligned to the cylindrical pencil alignment guide hole, into which the pencil is inserted. A sharp blade is mounted so that its sharp edge just enters the shaping cone. The pencil is inserted into the sharpener and rotated while the sharpener is held motionless. The body of the sharpener is often contoured, ridged or grooved to make the small block easier to firmly grip.

The blade inside the sharpener shaves the wood and graphite tip of the pencil, while the shavings emerge through a slot along the blade edge. It is important that the cylindrical alignment hole closely fit the diameter of the pencil to keep the pencil from wobbling; causing stepped or lurching cut-depths and point breakage. Another important feature is a larger clearance hole at the end of the cone allowing sections of the pencil lead which break away to be removed with only minor inconvenience. Prism sharpeners can be bare or enclosed in a container to collect the shavings. Enclosed sharpeners can be harder to clear in the event of a blockage. The base of such a sharpener is typically made of aluminium or hard plastic.

Moderate care is needed to not break the tip of the pencil being sharpened, losing the result of work immediately. However, because pencils may have different standard diameters in different nations, imported sharpeners may have non-standard-sized alignment guide-holes, —if it's too-small the pencil cannot be inserted, while too-big (or missing,) and the tip of the pencil constantly breaks off,— making sharpening attempts futile. A few prism sharpeners are hand-cranked, as in the photo above. Prism sharpeners may be right- or left-handed, requiring clockwise or counter-clockwise rotation of the pencil being sharpened.

Blade sharpeners

Unlike prism sharpeners, blade sharpeners do not rotate around the pencil being sharpened and may be viewed as just a special form of knife with a mechanical guide for increased safety and convenience. Some models directly hold replaceable shaving razor blades, others have permanently fitted blades. Blade sharpeners may require more skill, but they allow one to sharpen the tip of the pencil into any desired shape, whereas prism sharpeners have a fixed sharpening angle and produce

circular symmetry.

While most blade sharpeners are simple and hand operated, some devices in the past were crank operated, using mechanisms to convert crank rotation into linear motion.[7]

Cylindrical (planetary) sharpeners

A larger, stationary mechanical sharpener can be mounted on a desk or wall and powered by a crank. Typically, the pencil is inserted into the sharpener with one hand and the crank turned with the other. This rotates a set of helical cylindrical cutters in the mechanism, set at a diverging angle to each other. This quickly sharpens the pencil, with a more precise finish than the simpler blade device.

Advanced models have a spring-driven holder for the pencil (the pencil advances into the mechanism while being sharpened). Some versions also offer a regulator of the desired sharpness (it is not always desired to make the graphite core needle-sharp). Such sharpeners may be very easy to use even by children, but may be more expensive than prism sharpeners. Some such rotary sharpeners have only one burr cylinder. The casing of the sharpener is the repository for the pencil shavings, and needs to be emptied periodically. These mechanisms are also called planetary sharpeners,[7] in reference to their use of planetary gears.

Other systems

Some older models like the 1897 German Jupiter 1 used reversible rotary cutter-disks with cutting edges radiating from the center on each side. These were high-end models, quite large and expensive. Others simply used abrasives like sandpaper. In some cases an abrasive was used to shape the graphite core, while the wood was cut some other way.

Electric sharpeners

Electric pencil sharpeners work on the same principle as manual ones, but the cylindrical cutter is (or cutters are) rotated by an electric motor.[5] Some electric pencil sharpeners are powered by batteries rather than being plugged into a building's electrical system, making them more portable.

Auto-stop electric pencil sharpeners are able to sense when the tip of the pencil is long enough and then stop. In basic automatic pencil sharpeners the lead may become too long and break, and so users must be careful to time the action.

Razor knife

Artists and craftspersons may use a very sharp knife to sharpen pencils and other media freehand, without the use of any mechanical guides. The tip is cut into a triangle shape and then the edges of the triangle are trimmed down. This requires a total of 6 cuts and takes practice to master without breaking the lead.[8]

Specialized pencil sharpeners

Specialized sharpeners are available that operate on non-standard sizes of pencil, such as the large art pencils used in primary schools. Sharpeners that have two openings, one for normal pencils and one for larger art pencils are still fairly common. Some mechanical sharpeners have a large opening, with a rotating disk in front of it that has several holes of different sizes.

An artist's or draftsman's pencil sharpener leaves the graphite untouched and sharpens only the wood. (Some models can switch from standard to wood-only by an adjustment.) The graphite lead is then honed to a razor point with a lead pointer which sharpens only the lead without wood. Lead pointers are also used with mechanical leadholders which have removable/refillable leads.

Mechanical pencils dispense the graphite stick progressively during use and thus do not require sharpening. Such pencils are sometimes called "self-sharpening". If a sharper result is needed a stick with a smaller diameter is used.

Sharpeners with a single blade for use on wax crayons are available, and sometimes included in boxes of crayons. These often have plastic blades for the softer wax.

Carpenters may use carpenter pencils, the flattened shape of which stops them from rolling away, while still providing a constant line width. These pencils were traditionally sharpened with tools conveniently to hand, such as a plane or sandpaper. Rotating pencil sharpeners are now available for these too, where a rotating plastic collar holds the pencil in position, although they then sharpen them to the usual conical point as for a round pencil, abandoning all the distinctive aspects of the carpenter's pencil. A different design uses a sliding guide, which more closely mimics whittling the pencil by hand, using a sharp knife.

Gallery

Hand-cranked planetary sharpener, with cover in place

Hand-cranked planetary sharpener, with cover in place Hand-cranked planetary sharpener from 1950–60, with cover removed

Hand-cranked planetary sharpener from 1950–60, with cover removed A hand-cranked planetary sharpener with spring-driven pencil holder. The small handle behind the crank is the sharpness regulator

A hand-cranked planetary sharpener with spring-driven pencil holder. The small handle behind the crank is the sharpness regulator- An electric pencil sharpener. The mechanism is similar to the planetary sharpener, except there is a motor instead of a crank

See also

References

- ↑ Gerry Coughlan; Martin Hughes (2007). Irish Language and Culture. Lonely Planet. p. 74. ISBN 978-1-74059-577-3.

- ↑ “Carpenters pencil sharpener Patent” at google.com

- ↑ "20 Things You Didn't Know About... Pencils", Discover magazine, May 2007, retrieved 2009-04-30

- ↑ "Handheld Pencil Sharpeners". Retrieved 9 July 2011.

- 1 2 "Electric Pencil Sharpeners". Retrieved 9 July 2011.

- ↑ “New home for Ohio man's pencil sharpener 'museum’” at sacbee.com

- 1 2 "Pencil Sharpeners". Retrieved 9 July 2011.

- ↑ "razor knife".

External links

| Wikimedia Commons has media related to Pencil sharpeners. |

| Look up pencil sharpener in Wiktionary, the free dictionary. |

- The Electronic Pencil Sharpener

- Top 10 Best Electric Pencil Sharpeners In 2016

- Antique Pencil Sharpeners

- Collector of pencil sharpeners (in French and partly in English)

- Dutch Collector of pencil sharpeners